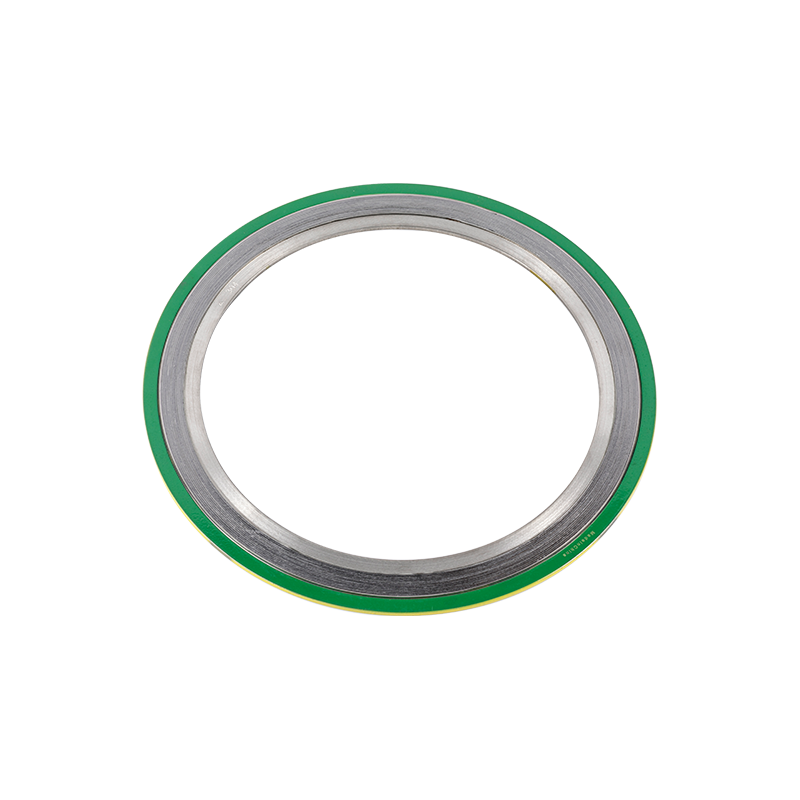

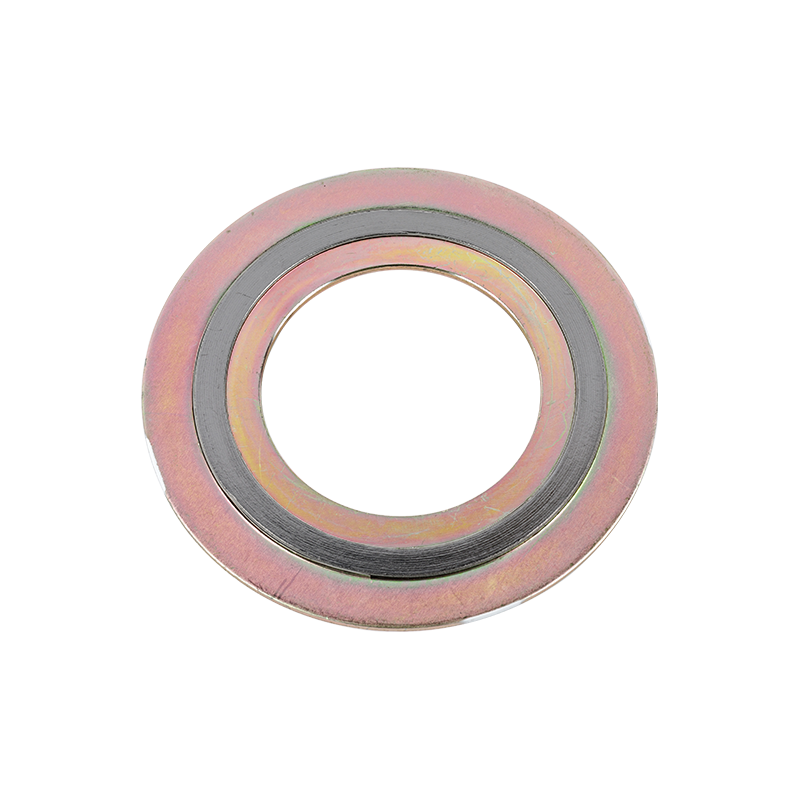

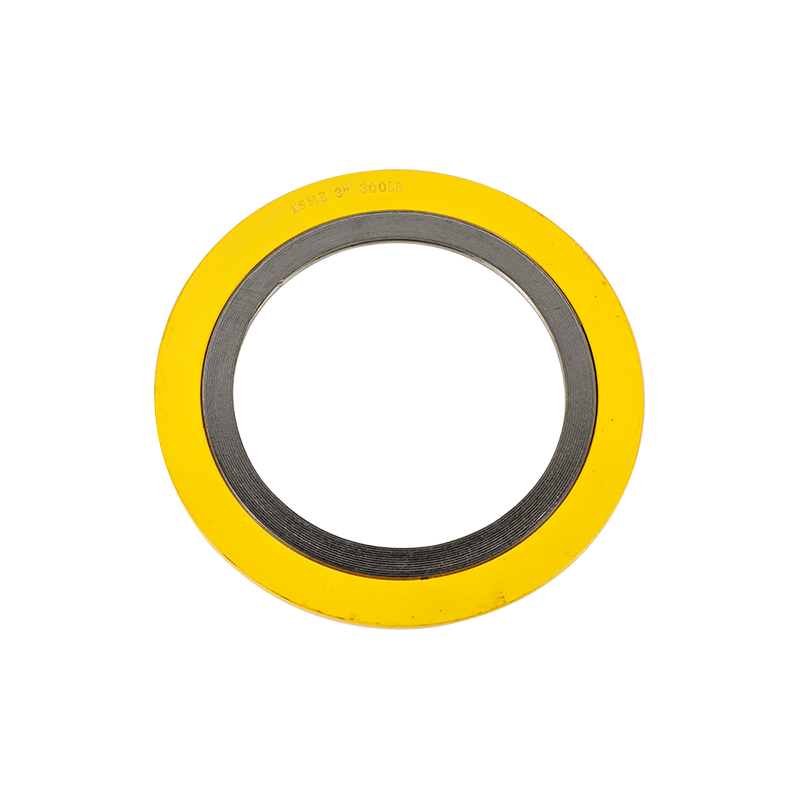

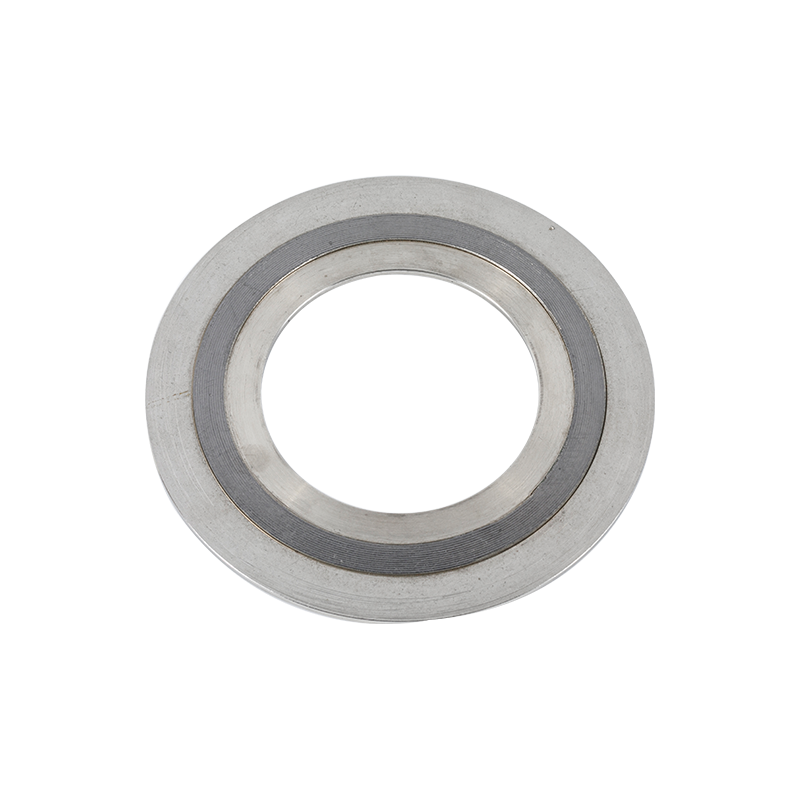

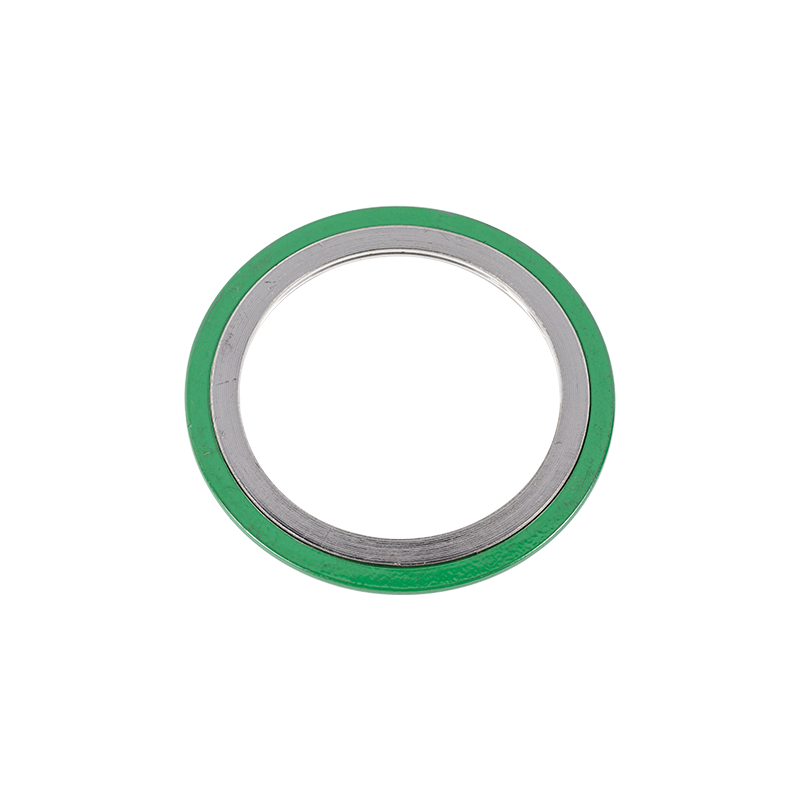

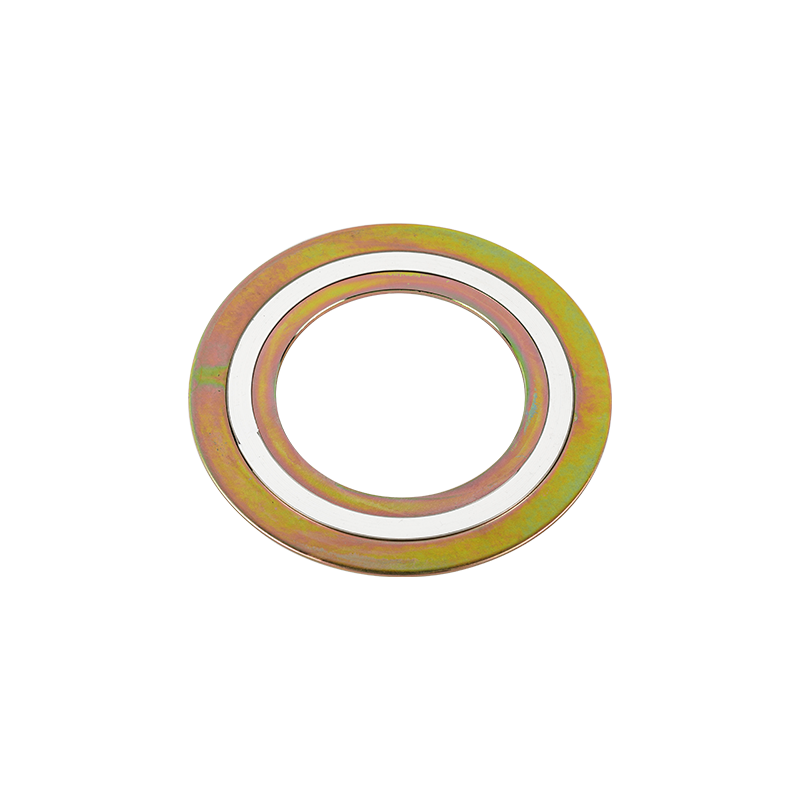

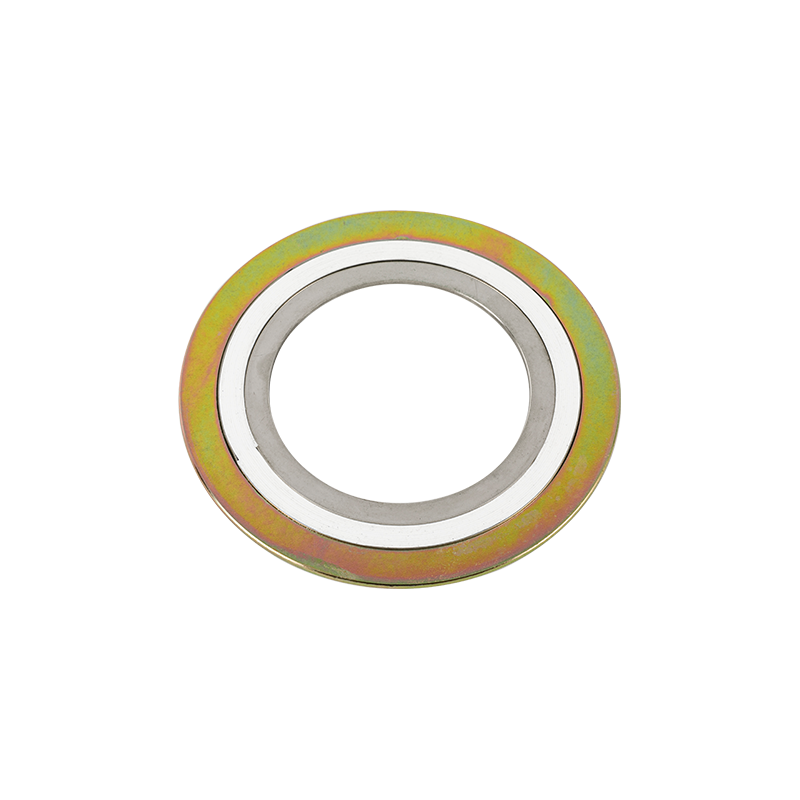

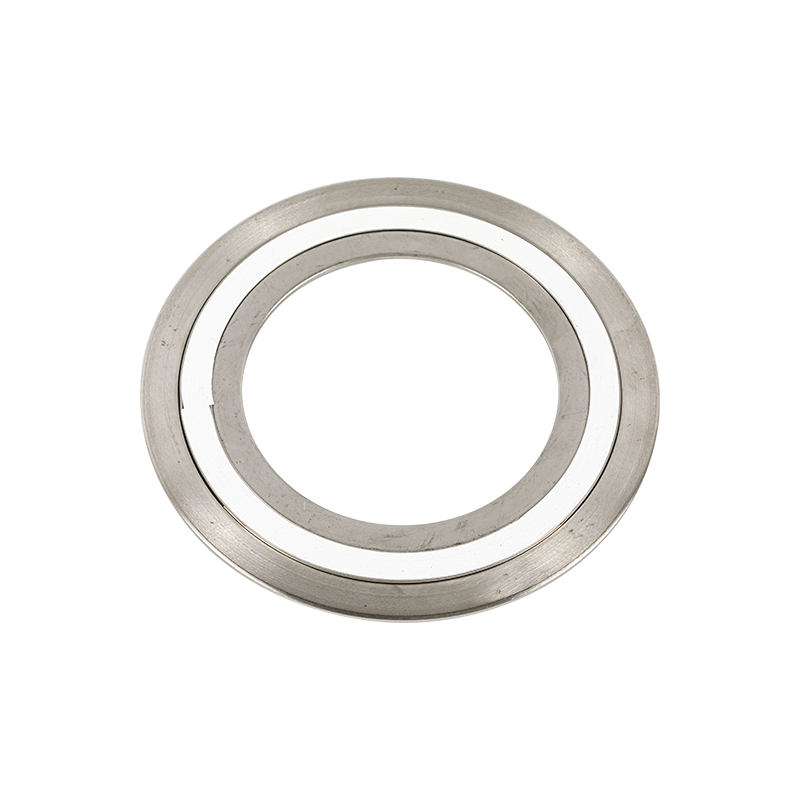

Exceptional Precision and Quality:

Die-formed rings are produced using a specialized manufacturing process that involves cutting and shaping metallic or non-metallic materials with high precision. This process ensures the rings are crafted to exact specifications, resulting in consistent dimensions and exceptional quality. The precision engineering of die-formed rings guarantees a secure and reliable seal, minimizing the risk of leaks or failure even in demanding environments.

Versatile Applications:

Die-formed rings find extensive applications in industries where sealing is critical. These rings are commonly used in pipelines, valves, pumps, engines, compressors, and other mechanical systems. Die-formed rings are suitable for sealing fluids, gases, or even high-pressure environments. Their versatility allows them to meet the sealing requirements of various industries, including oil and gas, chemical processing, pharmaceuticals, automotive, and more.

Chemical Compatibility:

Die-formed rings can be manufactured using a wide range of materials, such as metal alloys, rubber, plastics, or even exotic materials like PTFE. This versatility allows for compatibility with different chemical substances or media. Die-formed rings can withstand aggressive or corrosive environments, ensuring the integrity of the seal and preventing leaks or contamination. The ability to select the appropriate material for specific applications is crucial in ensuring effective sealing performance.

Resistance to Temperature and Pressure:

One of the key advantages of die-formed rings is their ability to withstand extreme temperatures and pressures. The materials used in their construction are carefully selected to withstand high or low temperatures, ranging from cryogenic applications to high-temperature processes. Die-formed rings also exhibit excellent resistance to pressure, maintaining a secure seal even under intense operational conditions. This quality ensures the integrity and longevity of the sealing system, contributing to overall operational efficiency.

Reliability and Durability:

Die-formed rings are designed for durability and long-term reliability. The precision engineering and high-quality materials used in their manufacture allow them to withstand harsh operating conditions, resist wear and tear, and maintain their sealing capabilities over an extended period. The robustness of die-formed rings reduces the need for frequent replacements or maintenance, resulting in cost savings and improved productivity.

Ease of Installation:

Die-formed rings offer ease of installation due to their precise dimensions and consistent shape. They can be easily inserted into the designated sealing areas without the need for specialized tools or extensive adjustments. The simplified installation process saves time, ensuring operational efficiency while minimizing the risk of errors or malfunctions due to improper installation.

English

English

中文简体

中文简体