A good gasket can make or break a joint, and there are a variety of different gaskets available in the market. Here's a quick review of the different types of gaskets. In addition to being highly durable, these types of gaskets can also be customized to meet any client's requirements. We also offer these products at the most competitive prices, so you can save money while purchasing them.

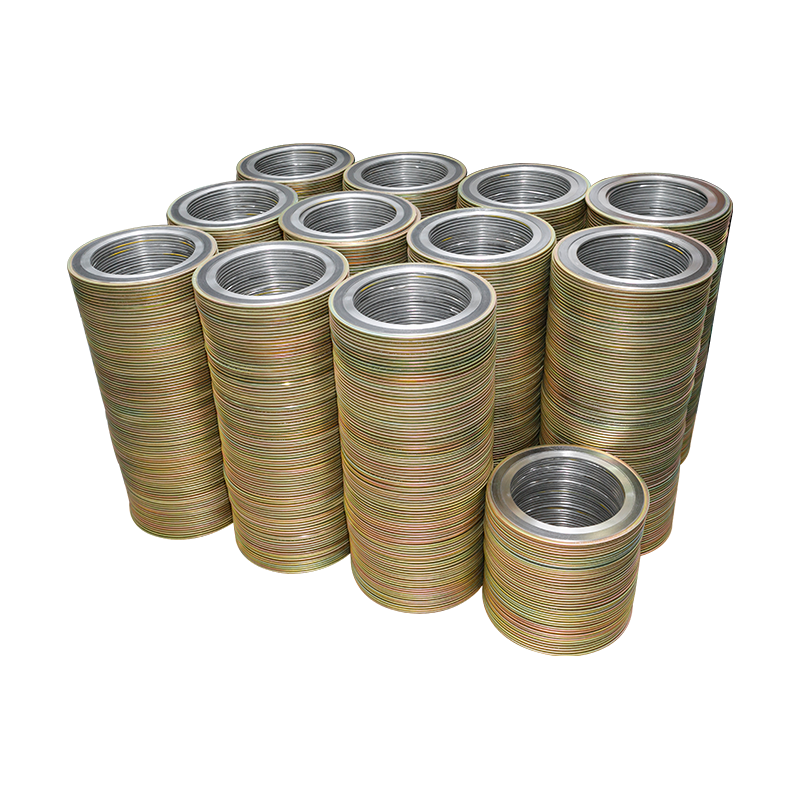

Corrugated metal

Corrugated metal flange gasket is an ideal choice for piping systems that require minimal load transfer. Its core is made of corrugated metal with an inner eyelet design that prevents media contamination. A corrugated gasket is generally larger than the flange's ID and must be centered. In order to achieve a perfect seal, it must be sized at Die-formed Ring least 1/8 inch larger than the flange's ID.

Corrugated metal gaskets are versatile and reliable in their application. Corrugated metal gaskets are used with standard flanges and heat exchangers. Due to their chemical and fire resistance, they can handle high-temperature environments. They are easy to install and require low available loading. Corrugated metal flange gaskets are used in a variety of applications and are particularly suited for applications where a tight seal is required.

Lens type

Lens gaskets are line contact seals that are typically used in pressure vessel heads and high-pressure piping systems. They feature a spherical surface and require special machining on flanges. This type of gasket requires extensive drawings and technical specs to determine proper dimensions and design. In addition, it is essential to obtain accurate and complete drawings for lens gaskets before determining the application.

The materials used to manufacture lens gaskets should be softer than the flange. This is necessary to avoid plastic or elastic deformation of the gasket. This also helps prevent the gasket from over stressing the lens ring. The gasket material used for lens rings should also be softer than the flange, to avoid excessive stress on the gasket. For non-standard lens rings, the gaskets should be made of softer materials that can accommodate high compressive loads.

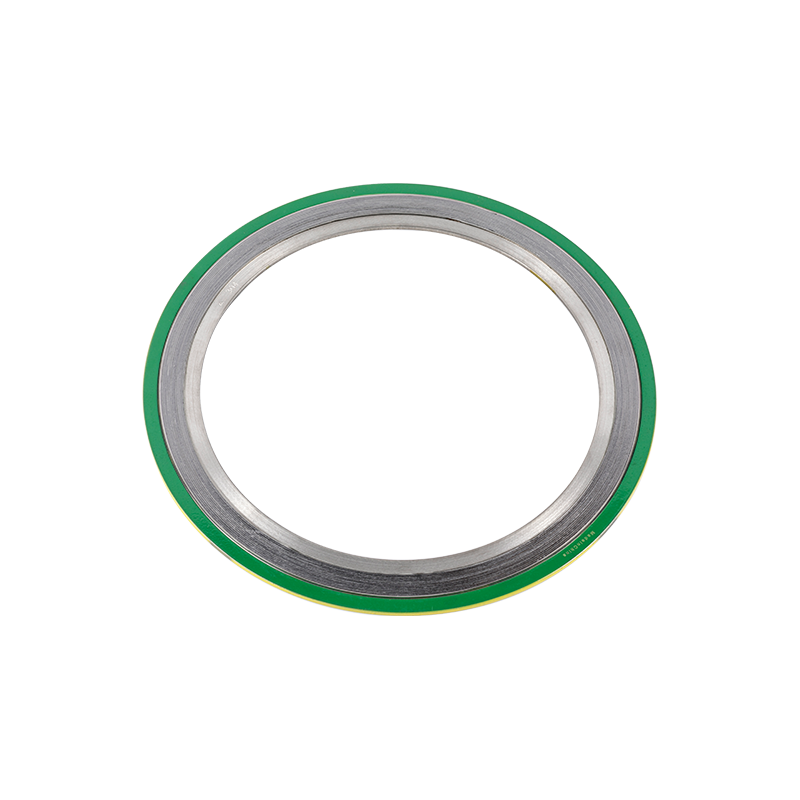

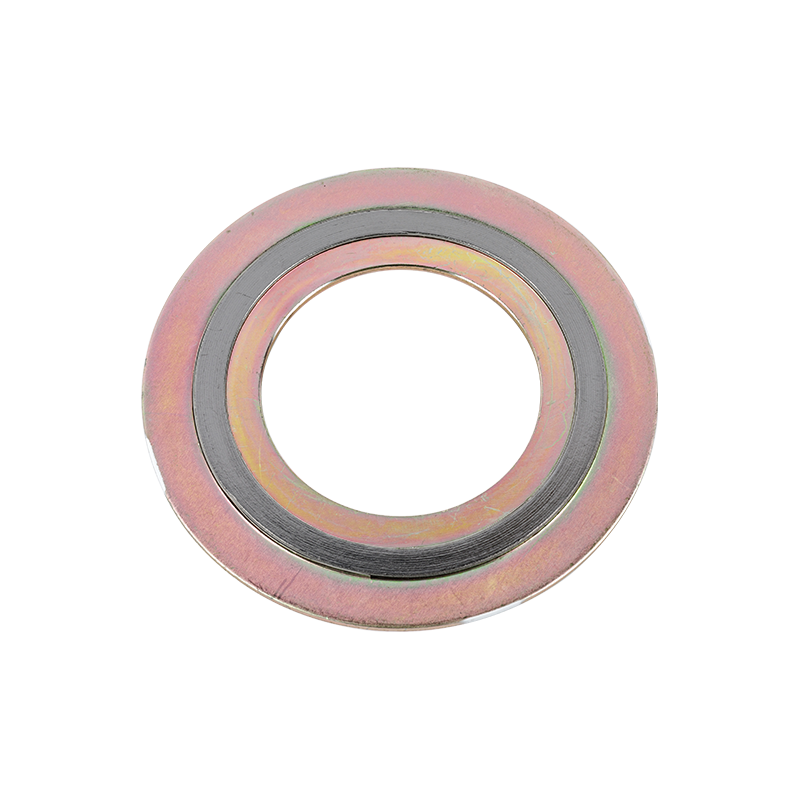

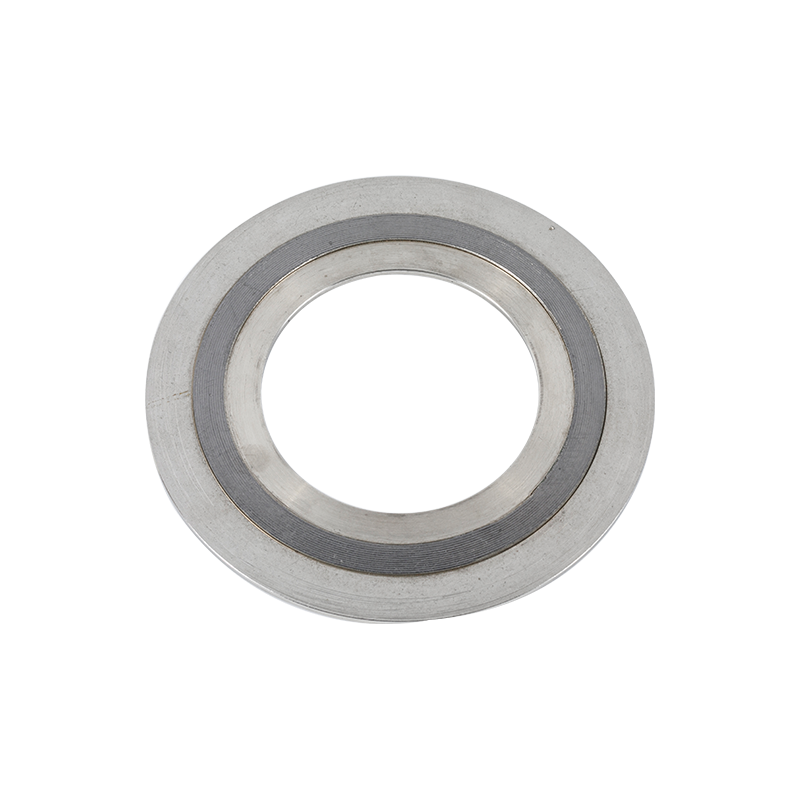

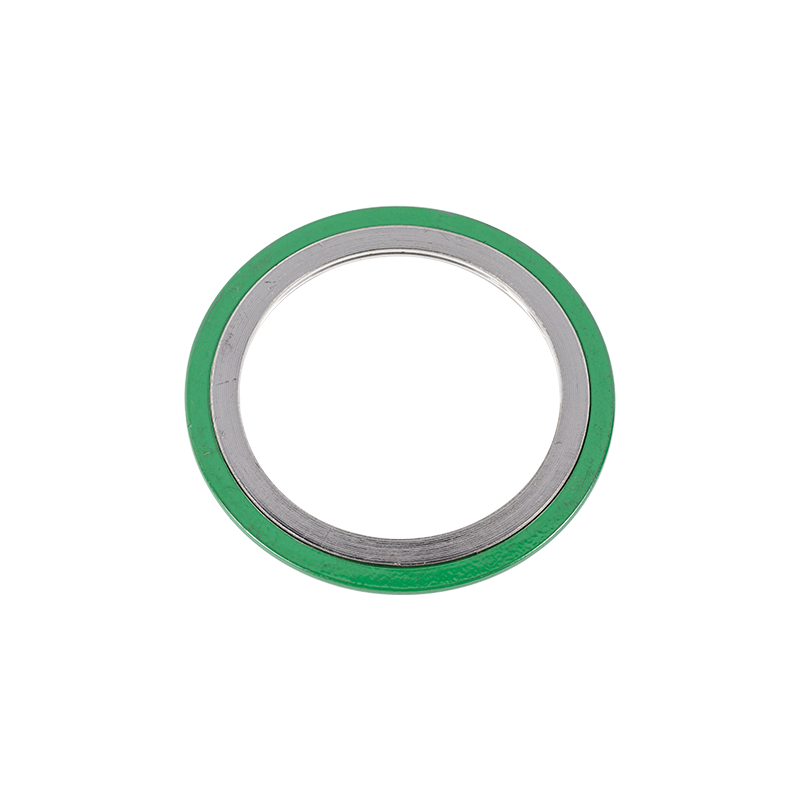

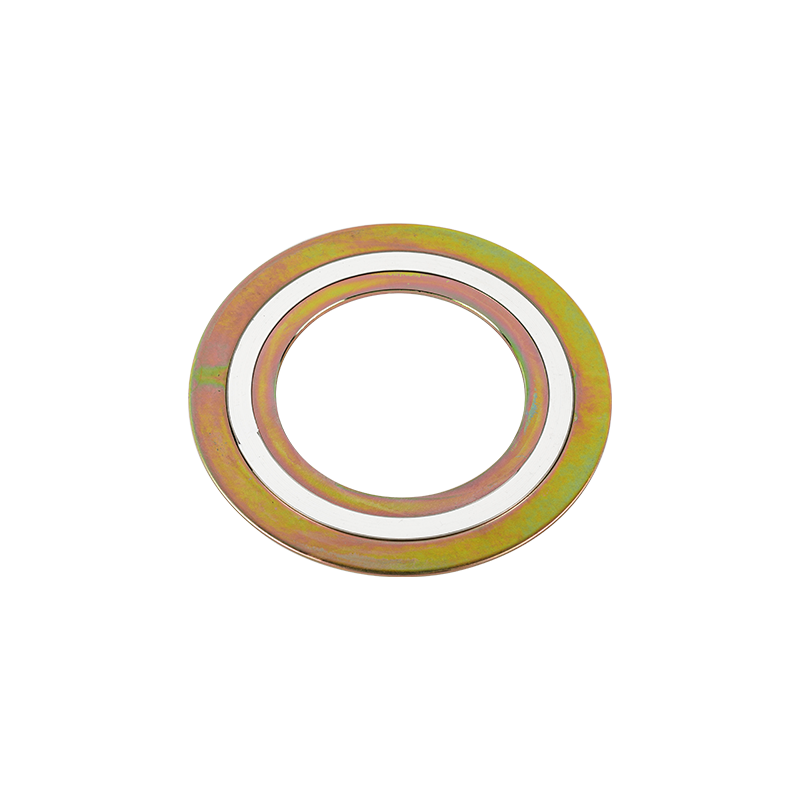

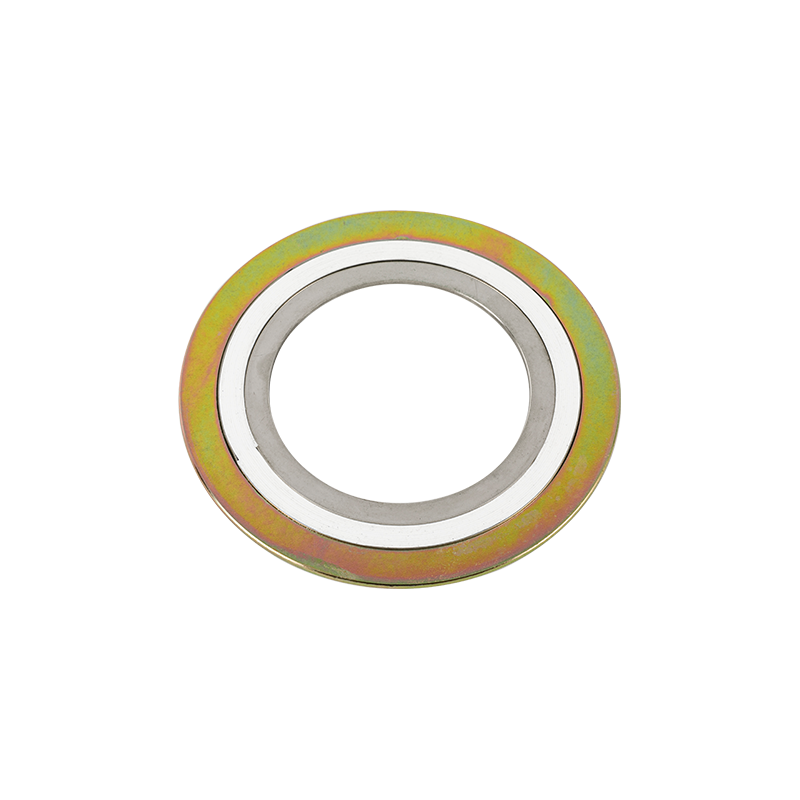

Ring type joint

A ring type joint is a metal-to-metal connection that is often found in equipment. When the joint is open, it can collect dirt and moisture. Because the sealing surface is very narrow, even a small crack or ding could cause a leak. For a tight seal, the ring gasket and grooves must be perfectly aligned, and they must remain that way throughout the operating cycle. If the flanges are made of dissimilar metals, alignment is vital.

There are several different types of ring type joint gaskets. Some are oval, while others are octagonal. The shape of the ring depends on the type of gasket, but the basic principle is the same. Metal gaskets are used in applications where pressures and temperatures are high. Because of their high temperature and pressure resistance, they can withstand high temperatures and pressures.

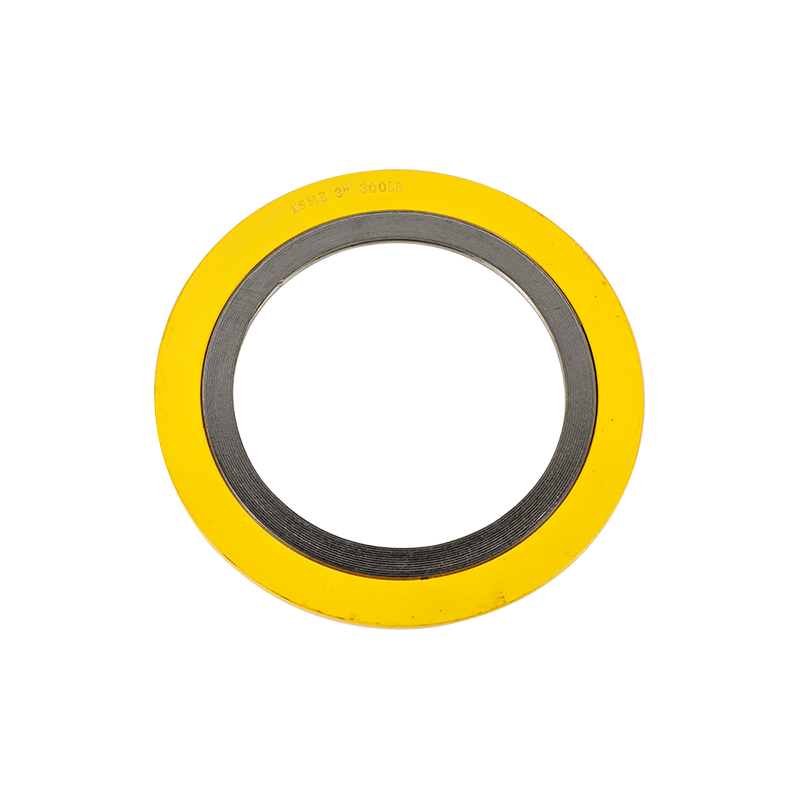

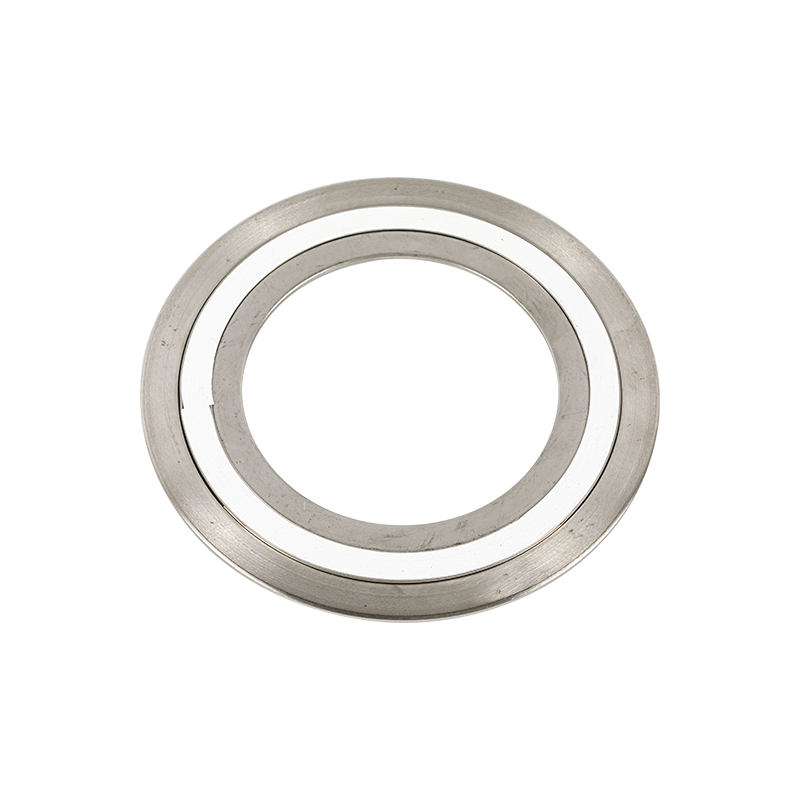

PTFE

PTFE metallic fusion flange gaskets are ideal for pipe lines and other applications where flexibility is necessary. These gaskets fit around the flange to keep it in place. Soft PTFE Gaskets are flexible, and are often used for high pressure pipelines. Gasket Suppliers offer a variety of sizes and types. They are also available in different designs and materials. PTFE gaskets are a good option for high pressure pipelines and flat surface connections.

PTFE metallic fusion gaskets have an inner metal ring that serves as a compression stopper. This keeps solids from building up inside the flange and reduces the turbulent flow of process fluids. They are available in both male and female versions. This type is recommended for flanges with a class 900 or higher. The solid outer ring also offers extra radial strength and compression limit.

English

English

中文简体

中文简体