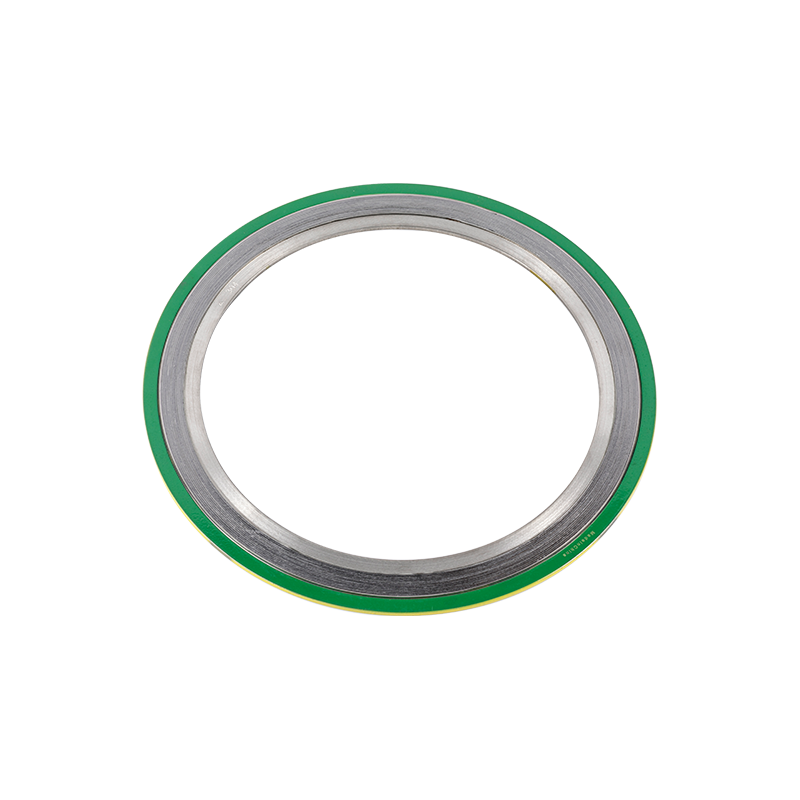

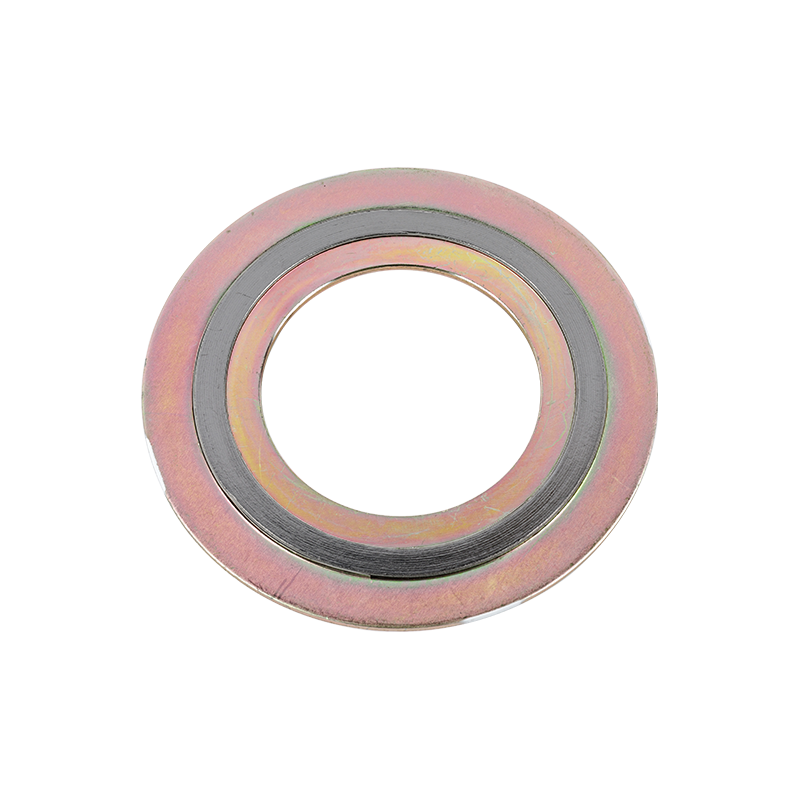

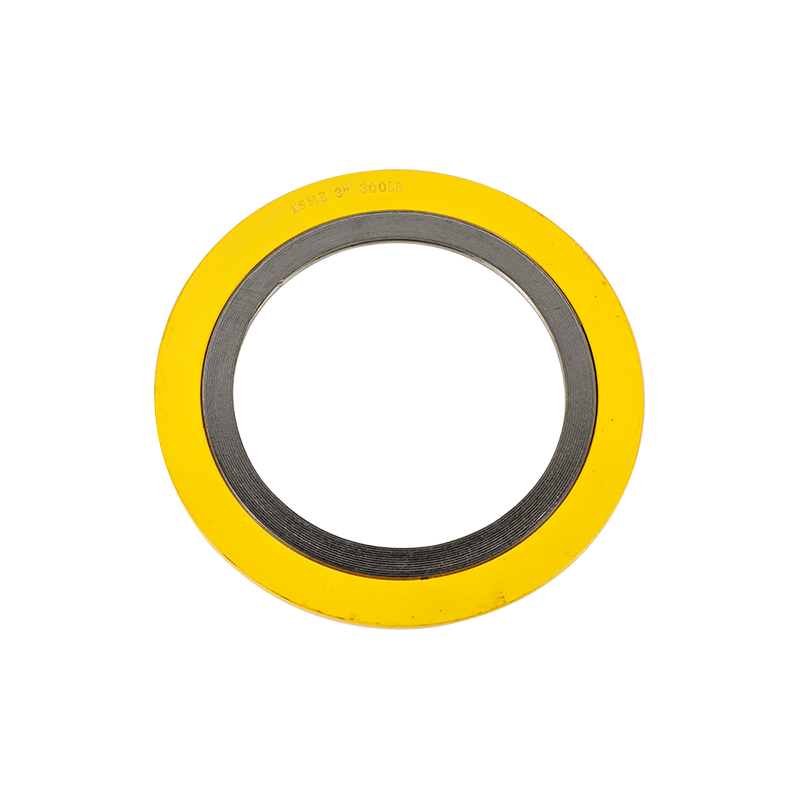

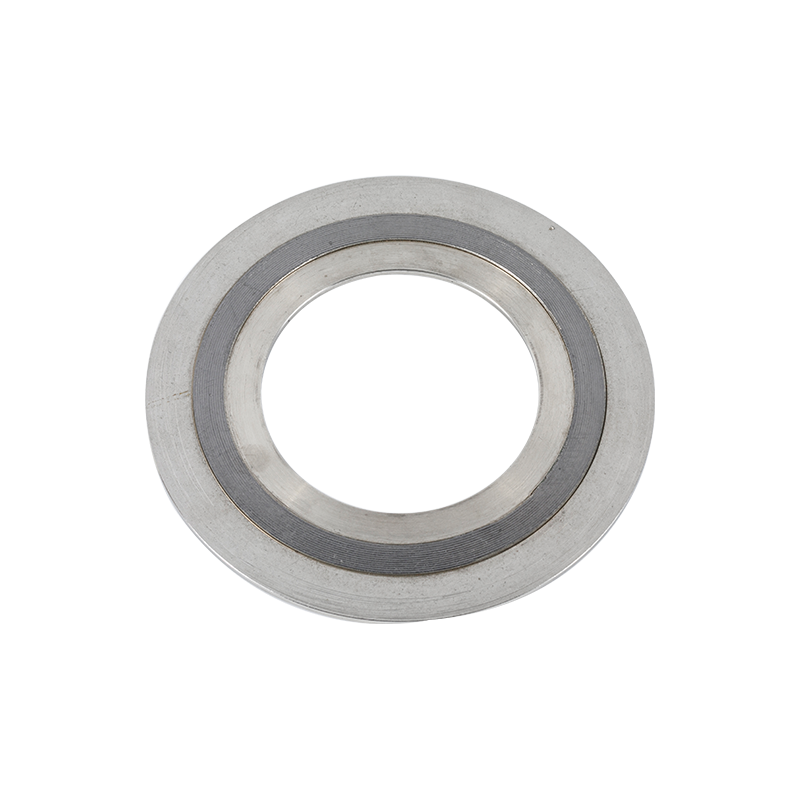

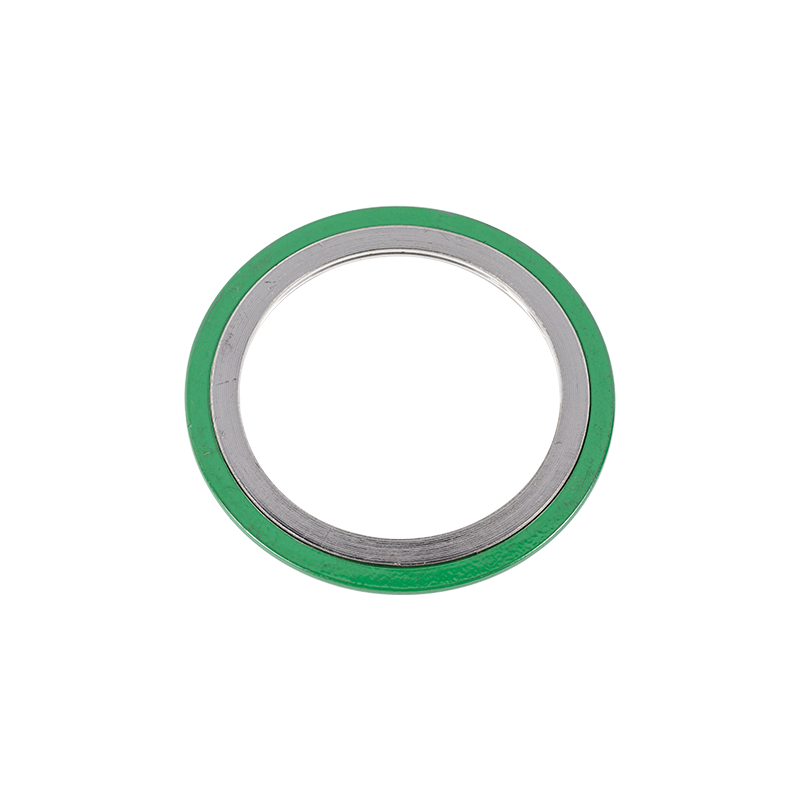

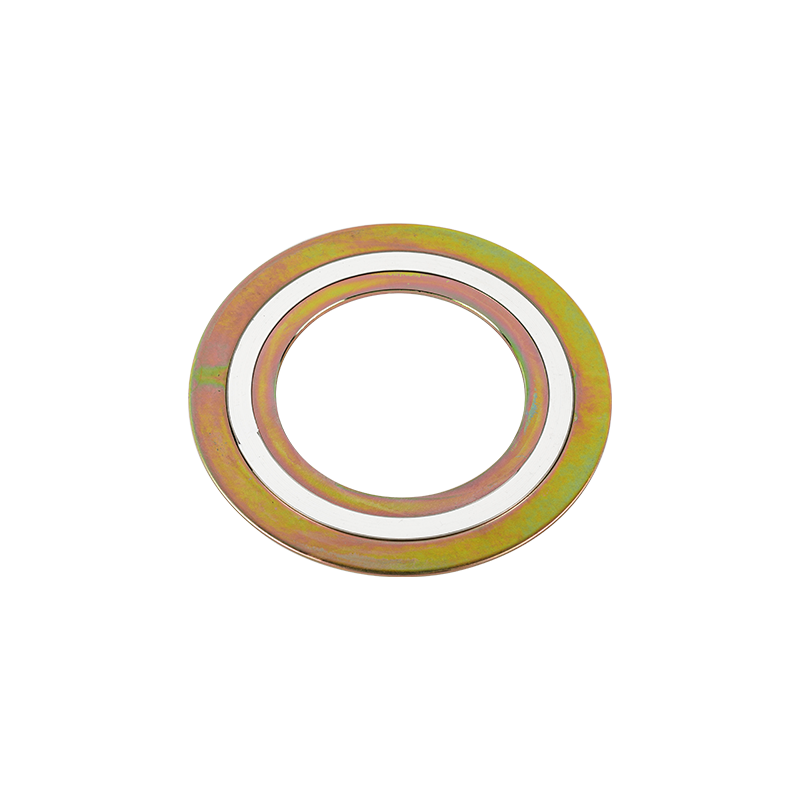

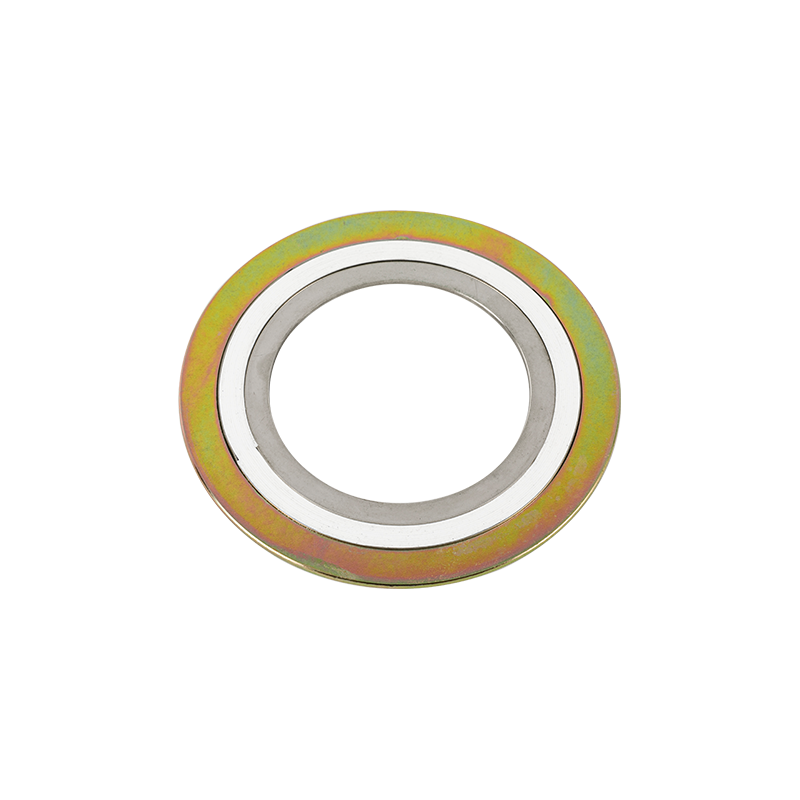

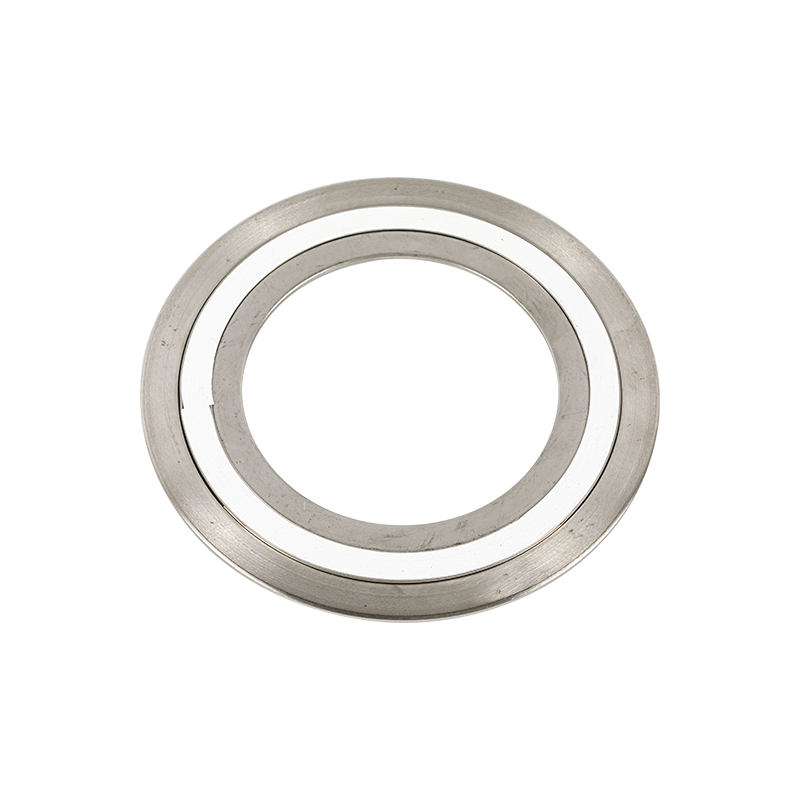

Die-formed rings are critical components used in various industries for sealing applications where reliability and performance are paramount. To achieve optimal compression characteristics, it is essential to implement specific measures during the production process.

1. Material Selection:

Choosing the right material for die-formed rings is crucial for achieving optimal compression characteristics. Different materials exhibit varying levels of elasticity, hardness, and resistance to chemicals and temperature. Consider the specific application requirements to select a material with suitable properties that can maintain compression and sealing performance over time.

2. Accurate Die Design:

The design of the die used in forming the rings plays a significant role in determining their compression characteristics. Precise die design ensures consistent dimensions and shape, resulting in uniform compression during installation. Utilize computer-aided design (CAD) software or engineering expertise to create an accurate die that replicates the desired specifications of the finished die-formed rings.

3. Precision Manufacturing:

Adopting advanced manufacturing techniques and machinery is crucial to ensure dimensional accuracy and maintain the desired compression characteristics. Modern CNC (Computer Numerical Control) machining allows for high precision, eliminating human errors and ensuring consistent results. Regular maintenance of manufacturing equipment is also essential to prevent wear and tear that could affect the compression capabilities of the rings.

4. Quality Control:

Implementing stringent quality control measures throughout the production process is vital for upholding optimal compression characteristics. This involves inspecting raw materials for consistency and quality, regularly checking die dimensions, and performing random sampling during production runs to verify the dimensional accuracy and compression properties of the die-formed rings. These quality control checks help identify and rectify any issues early on, ensuring consistent performance and customer satisfaction.

5. Testing and Certification:

To validate the compression characteristics of die-formed rings, it is essential to conduct appropriate testing. Compression tests measure the resilience and sealing performance of the rings under different levels of compression. These tests help identify the maximum compression range that the rings can withstand while maintaining a reliable seal. Additionally, obtaining certifications such as ISO 9001 assures customers that the die-formed rings they receive meet stringent quality standards.

English

English

中文简体

中文简体