High-temperature resistant spiral wound gaskets are essential in industries that operate under extreme conditions, such as high temperatures and pressures. These gaskets provide a reliable and efficient sealing solution, ensuring the integrity and safety of equipment and systems. However, proper installation is crucial for their effectiveness and longevity. Here are the key factors to consider when installing high-temperature resistant spiral wound gaskets:

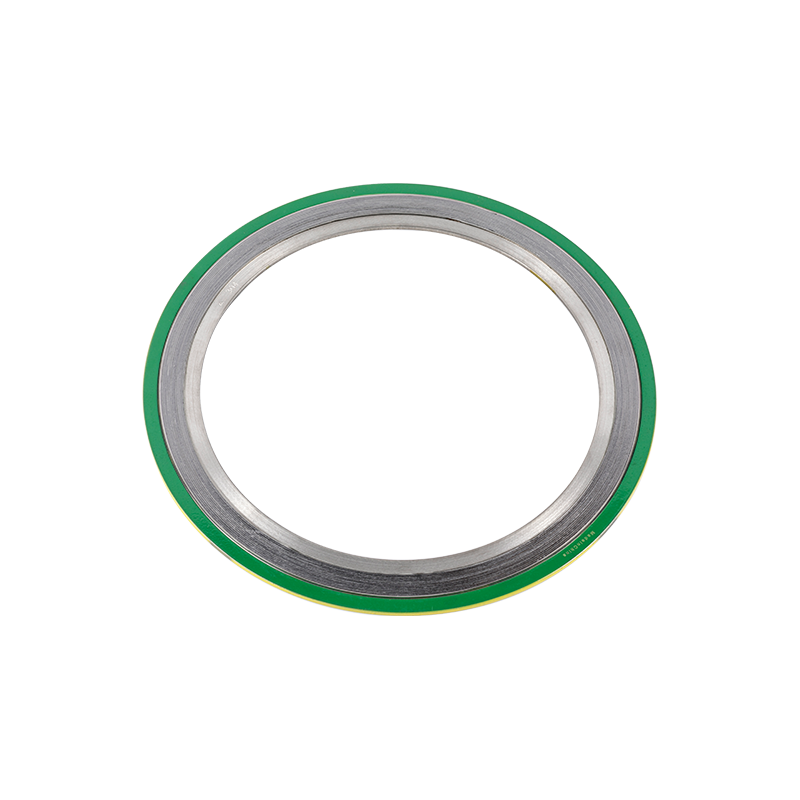

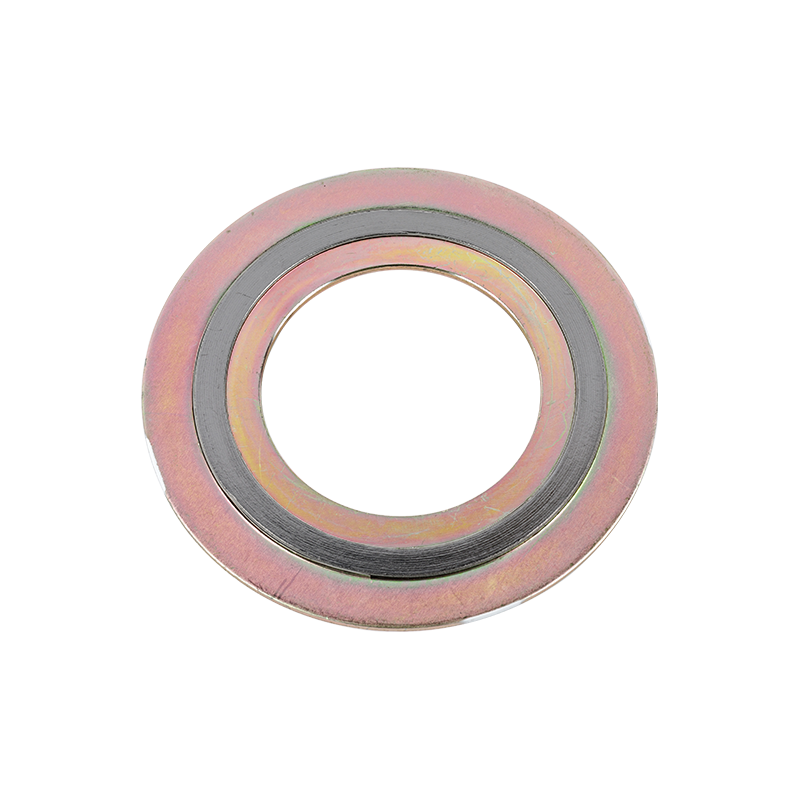

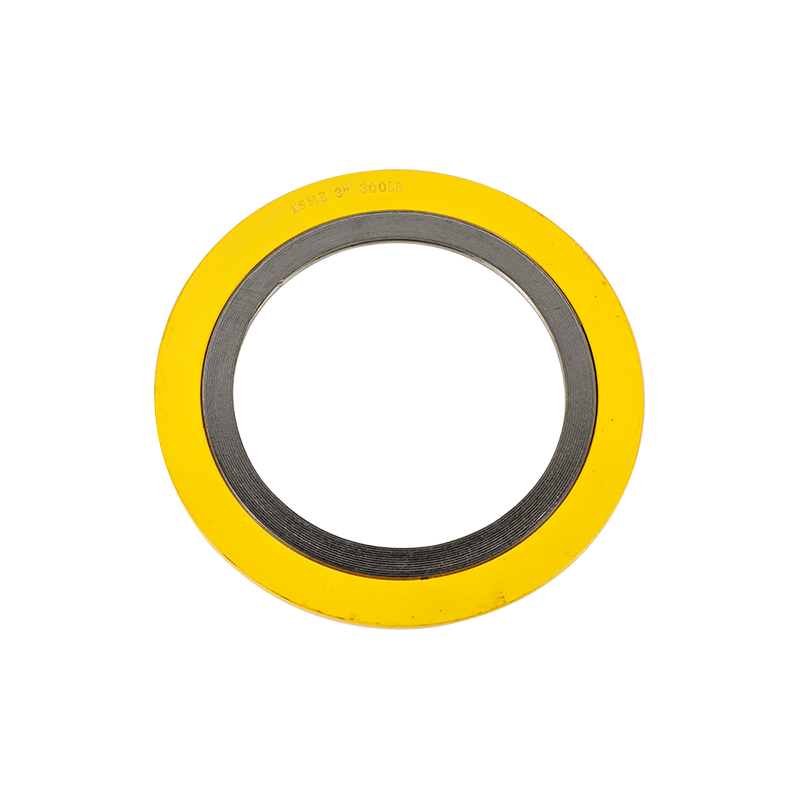

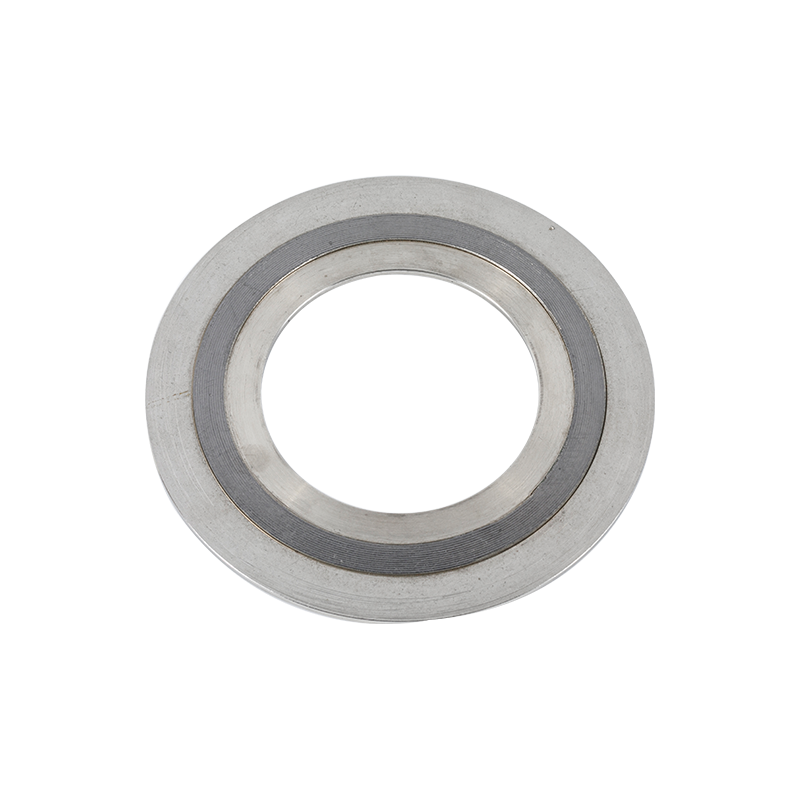

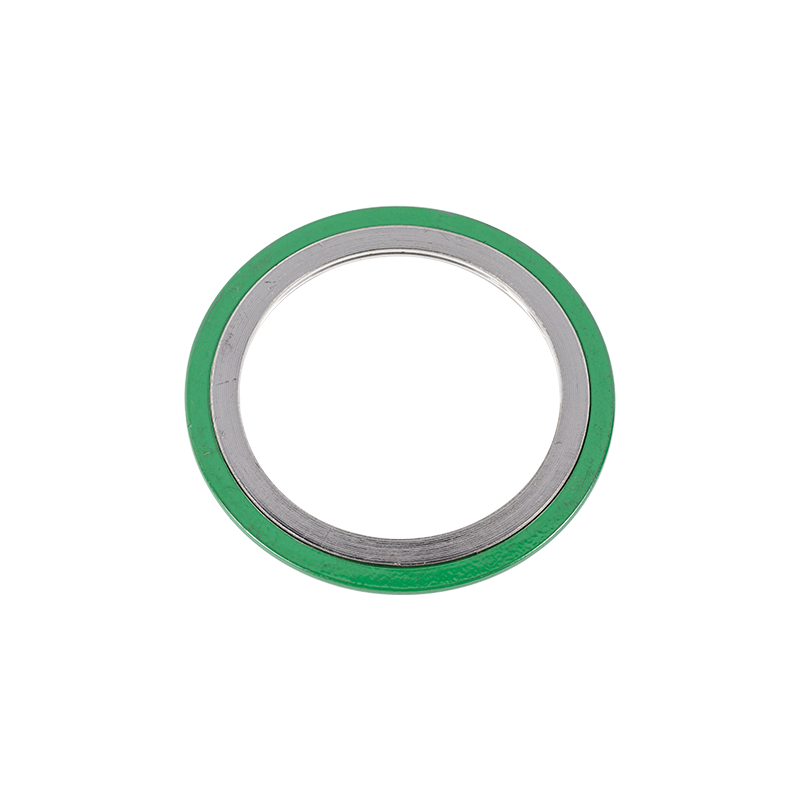

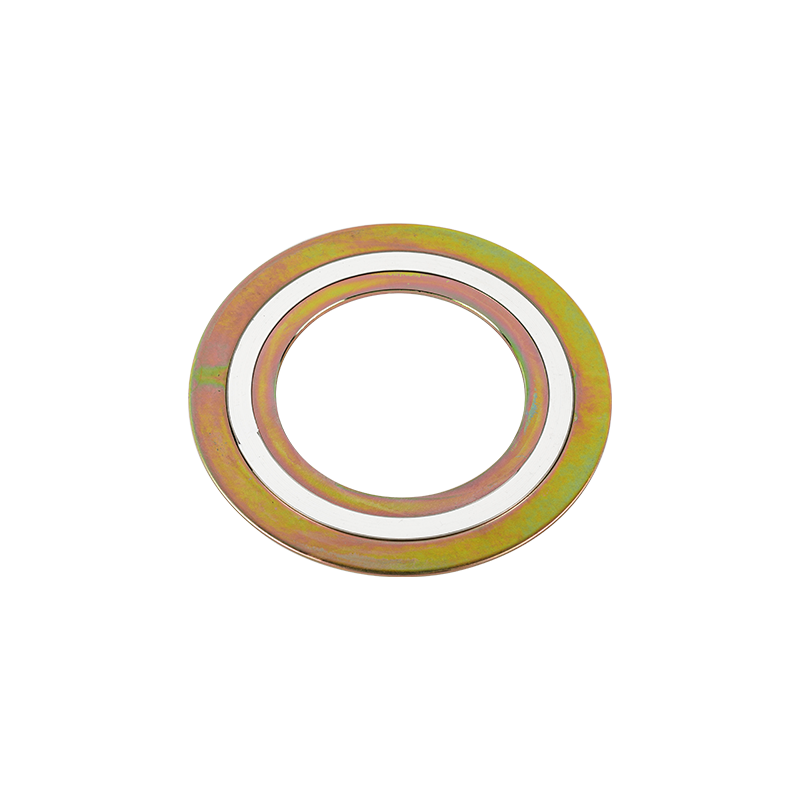

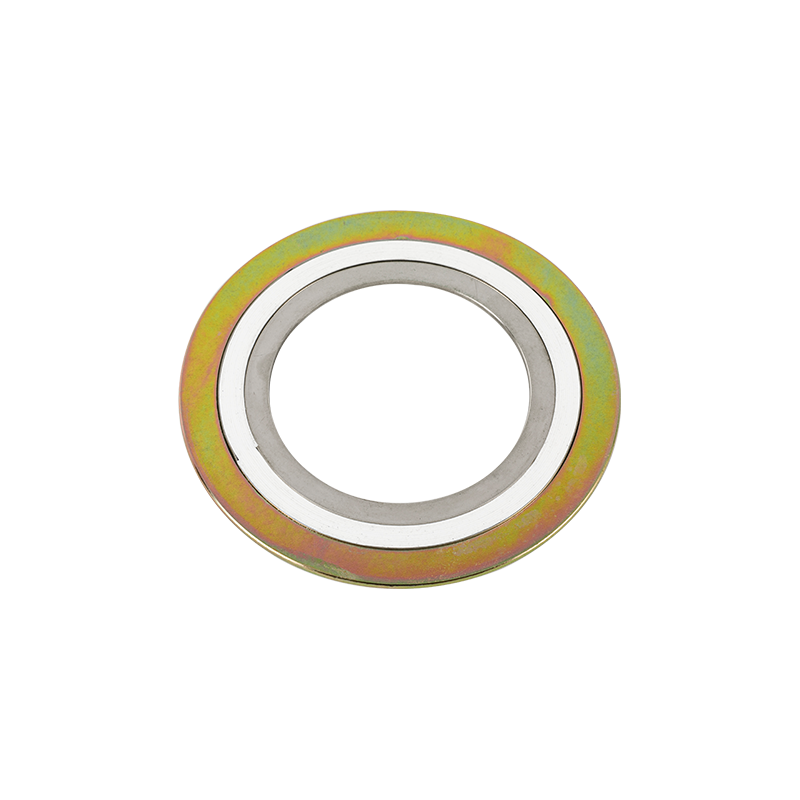

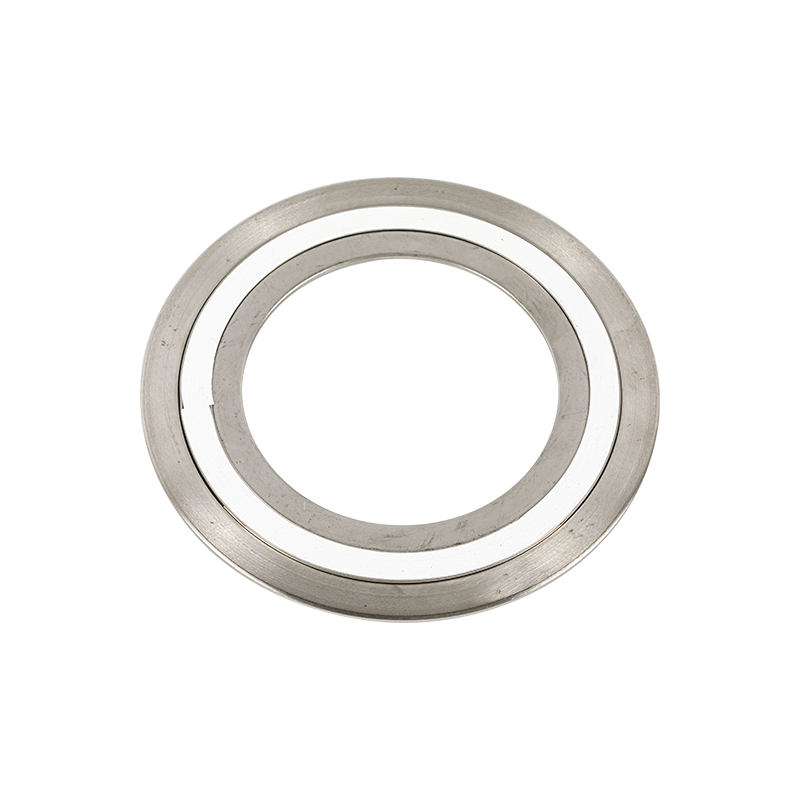

1. Gasket Material Selection:

Choosing the right gasket material is paramount. High-temperature resistant spiral wound gaskets are typically made from materials like stainless steel, graphite, PTFE, or a combination of these. Each material has its own unique properties and can withstand different temperature ranges. Consider the specific temperature requirements of your application and select a gasket material that can withstand those temperatures without compromising its sealing capabilities.

2. Surface Preparation:

Proper surface preparation is vital to ensure a tight seal. Clean the flange surfaces thoroughly to remove any contaminants, rust, or residue that can affect the gasket's performance. The flange surface should be smooth, flat, and free from any irregularities that could lead to leaks or gasket blowout. Use appropriate tools and techniques to achieve the required surface finish.

3. Correct Gasket Thickness:

The thickness of the spiral wound gasket plays a crucial role in achieving an effective seal. It is essential to select the appropriate thickness based on the flange design, operating conditions, and pressure requirements. A gasket that is too thin may not provide sufficient compression and sealing, while a gasket that is too thick can lead to excessive stress on the flanges, resulting in leaks or gasket failure. Refer to the manufacturer's guidelines or seek expert advice to determine the optimal gasket thickness.

4. Proper Compression:

Achieving the right compression is critical for a successful installation. Under-compression can lead to inadequate sealing, while over-compression can damage the gasket or cause leaks. Follow the manufacturer's recommendations or industry standards for the required compression load. Use an appropriate torque wrench and tightening sequence to ensure uniform compression across the flange surface.

5. Consider Flange Misalignment:

Flange misalignment can significantly affect the performance of a high-temperature resistant spiral wound gasket. It can cause excessive stress on the gasket, leading to leaks or premature failure. Take steps to minimize flange misalignment during installation, such as ensuring proper alignment of flanges, using alignment tools, or employing a controlled bolting technique.

6. Proper Bolt Tightening:

The correct tightening of bolts is crucial for gasket stability and integrity. Use the recommended torque values provided by the gasket manufacturer or consult industry standards. Tighten the bolts gradually and evenly in a cross pattern to achieve uniform compression and avoid excessive stress on the gasket.

English

English

中文简体

中文简体