Gasket thickness standard:

The thickness of the main body T: 2.2-3.2mm, the limit deviation is +2.0, 0; the thickness of the reinforcement ring T1: 2mm, the limit deviation is ±0.2.

The thickness of the main body T: 4.5-6.5mm, the limit deviation is +04., 0; the thickness of the reinforcement ring T1: 3-5mm, the limit deviation is ±0.3.

Nominal diameter <200, gasket body d2 (+0.5 0mm), d3 (0-0.8mm); inner and outer rings: d1 (+0.5 0mm), d4 (0-0.8mm).

250<nominal diameter<600, gasket body d2 (+0.8 0mm), d3 (0-1.3mm); inner and outer rings: d1 (+0.8 0mm), d4 (0-1.3mm).

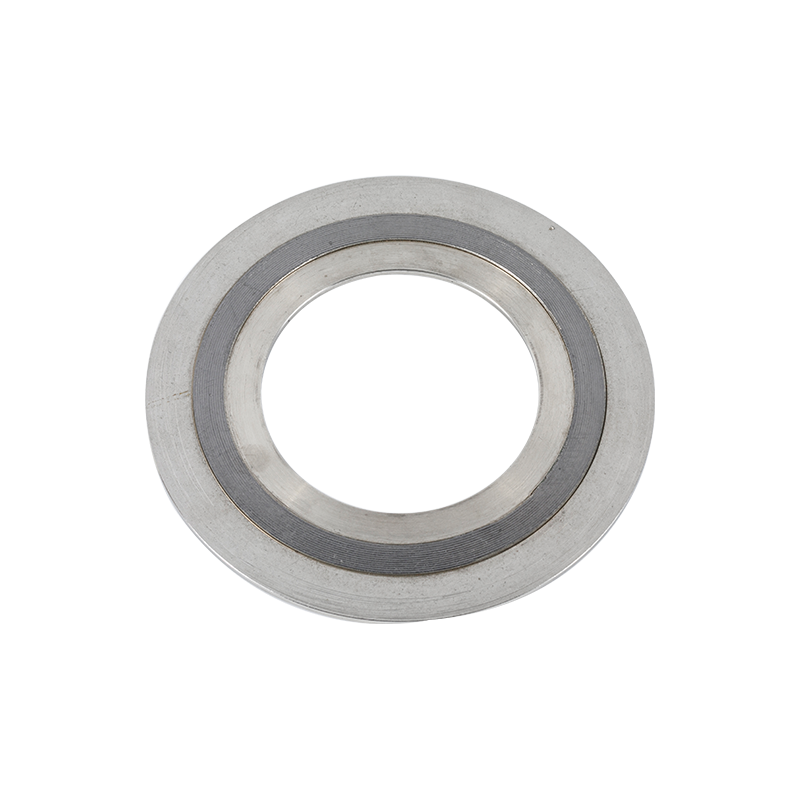

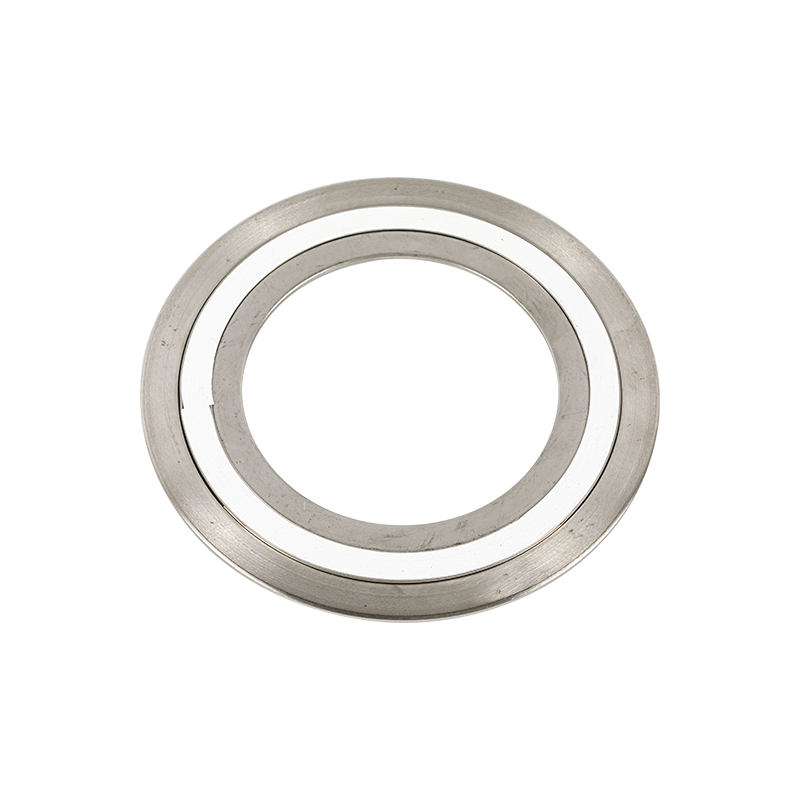

Material:

The material of the metal gasket is made of imported stainless steel, high carbon steel and brass through heat treatment and fine grinding. It has the characteristics of high precision, toughness and not easy to break. Among them, the material of high carbon steel has a certain elasticity, and the material of stainless steel is very tough.

Uses of metal gaskets: used in electronic instruments, mold manufacturing, precision machinery. This product can be used to solve machine maintenance problems when mold maintenance, mold measurement gap and shaking, swaying and instability due to mechanical aging. The sealing effect in flanged connections is also a great use for metal gaskets.

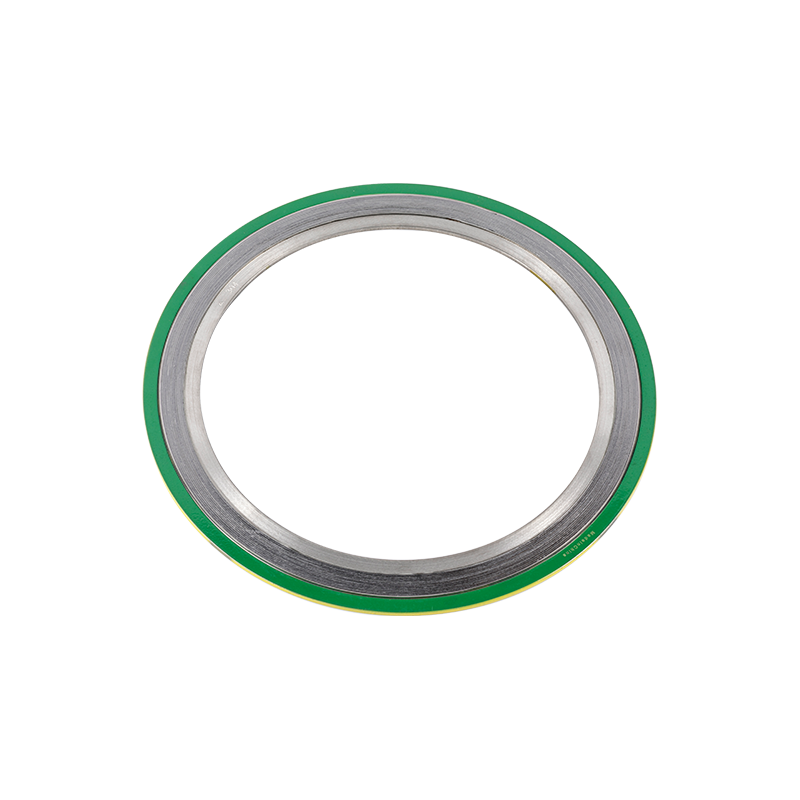

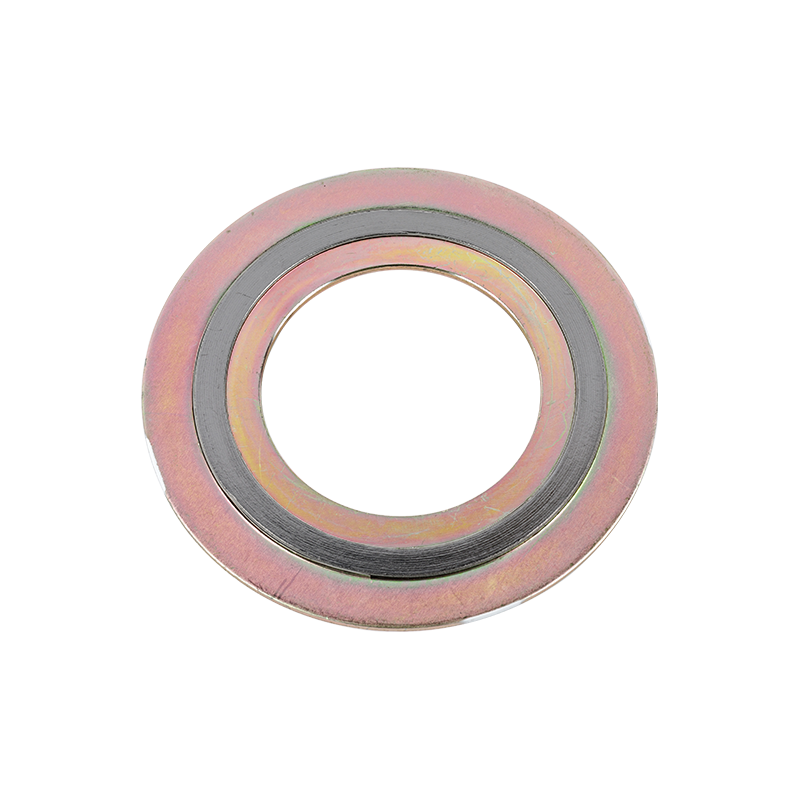

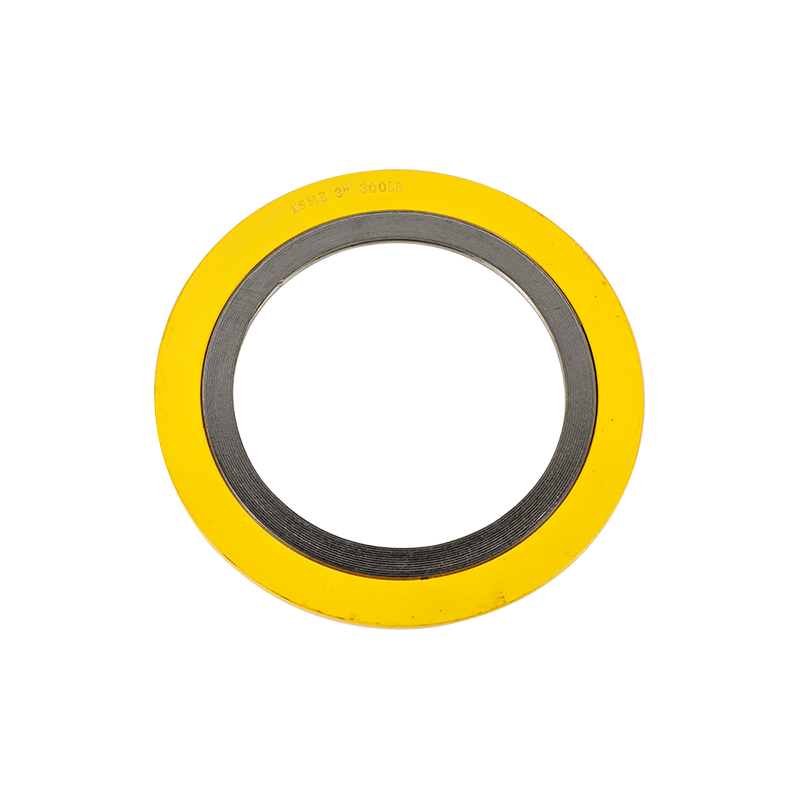

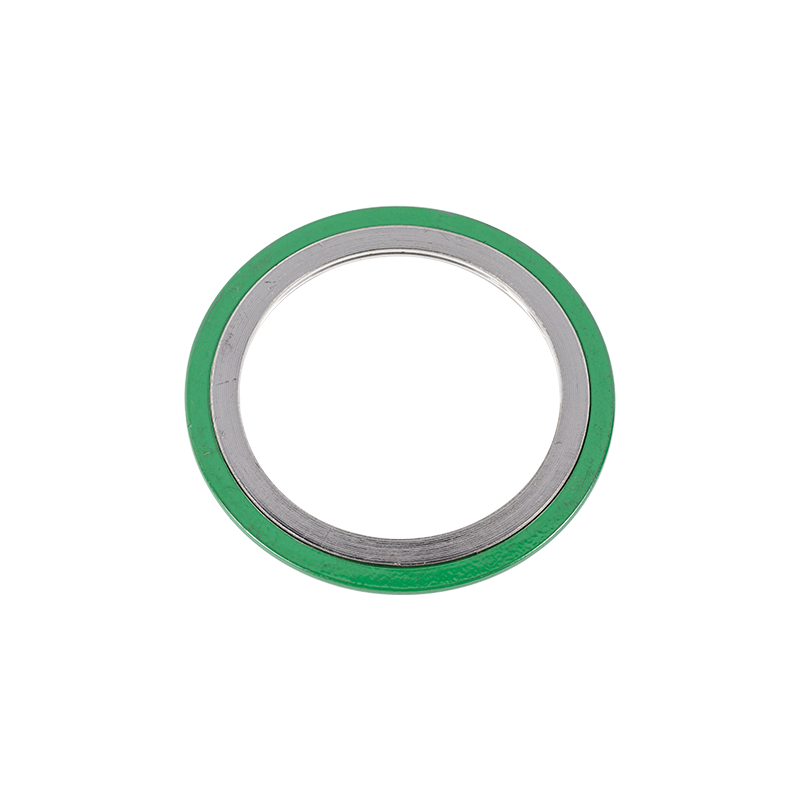

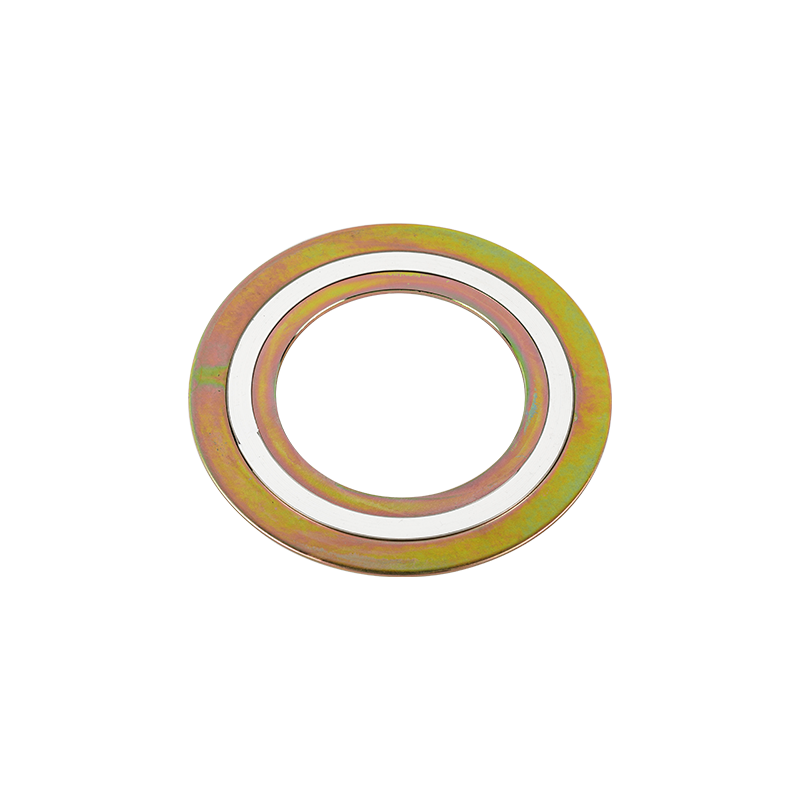

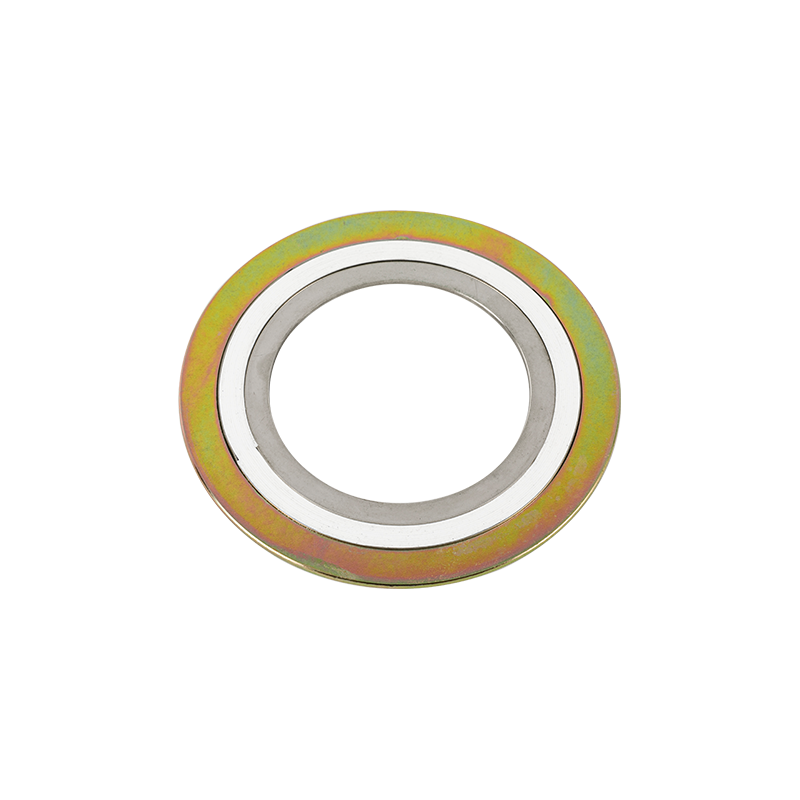

The full name of the gasket is flexible graphite metal wound gasket. The national standard number is JB/T6369-2005. This standard was first released in 1992 and revised for the first time by the China Machinery Federation in 2005. Mainly update and adjust the tensile strength, sulfur and chlorine content, and compression ratio of gaskets.

Gasket shape and size standard:

Gasket Standard

Nominal diameter <200, gasket body d2 (+0.5 0mm), d3 (0-0.8mm); inner and outer rings: d1 (+0.5 0mm), d4 (0-0.8mm).

250<nominal diameter<600, gasket body d2 (+0.8 0mm), d3 (0-1.3mm); inner and outer rings: d1 (+0.8 0mm), d4 (0-1.3mm).

650<nominal diameter<1200, gasket body d2 (+1.8 0mm), d4 (0-1.8mm); inner and outer rings: d1 (+1.5 0mm), d4 (0-1.8mm).

1300<nominal diameter<3000, gasket body d2 (+2.0 0mm), d4 (0-2.5mm); inner and outer rings: d1 (+2.0 0mm), d4 (0-2.5mm).

Multi-layer-Metal-Exhaust-Muffler-Gasket

Product Specification:

Exhaust pipe gasket

Exhaust pipe gaskets are generally divided into exhaust pipe interface gaskets, muffler sealing rings, exhaust pipe winding gaskets, etc. There are various forms of exhaust pipe gaskets according to different models and styles. The commonly used interface gaskets are graphite, which is a high -temperature resistant material. Or mica and stainless steel punched sheet are compounded into composite board and punched out. The product has super compression resilience and high temperature resistance and sealing performance. The muffler sealing ring is mainly made of metal wire mesh and high temperature resistant graphite and pressed into a spherical shape through the special treatment of ceramic powder, so that it has better lubrication and sealing performance. It is the first choice for sealing products in the exhaust system of automobiles or motorcycles. The car muffler sealing ring developed by our The company has been widely used and has developed many molds for different models. Exhaust pipe winding gaskets are generally used to seal the single-use circular joints of automobiles or motorcycles. The materials are generally stainless steel and graphite or asbestos, non-asbestos winding. There are two types of V-type and W-type. The exhaust pipe produced by our company Tracheal spiral wound gaskets have strong advantages and have been exported to Taiwan, South Korea, Europe and the United States and other countries and regions.

English

English

中文简体

中文简体