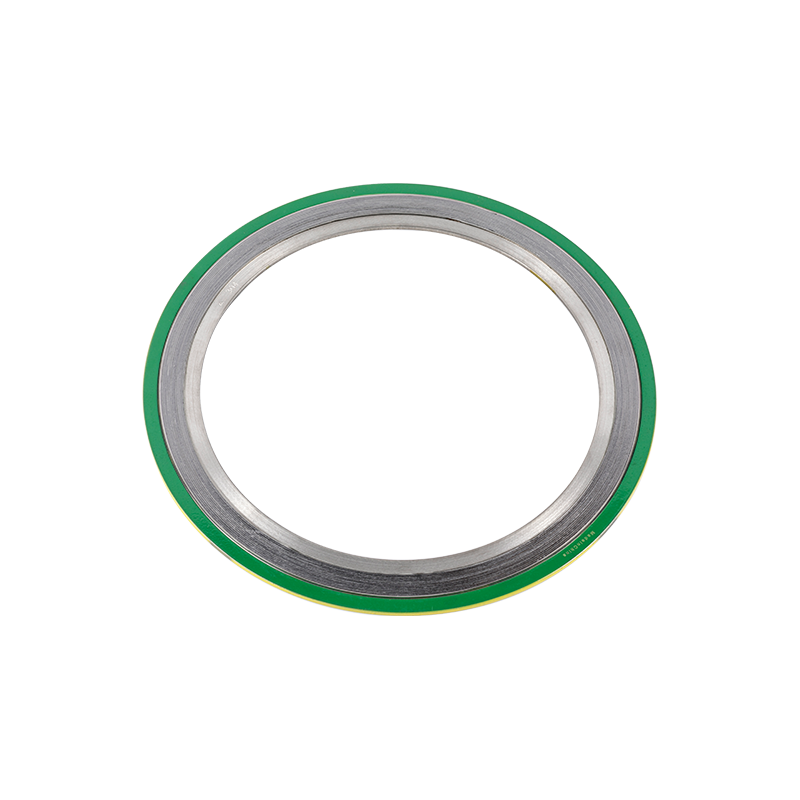

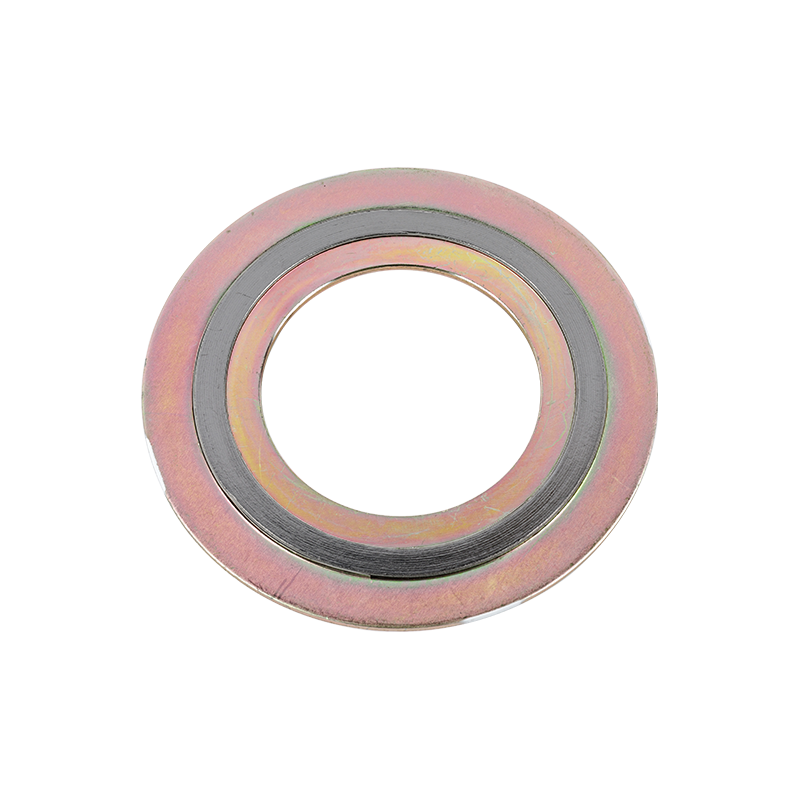

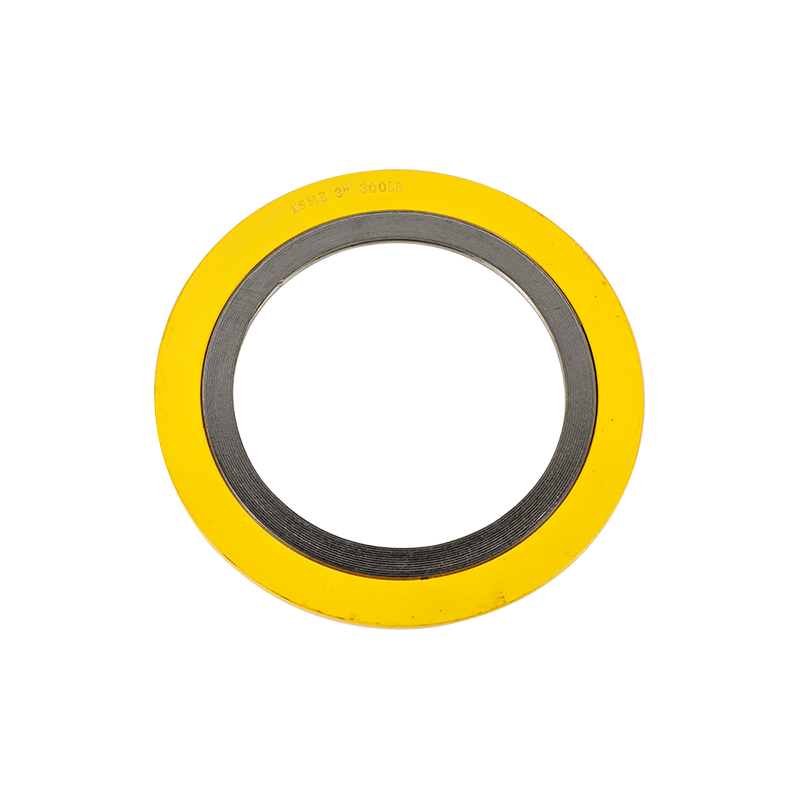

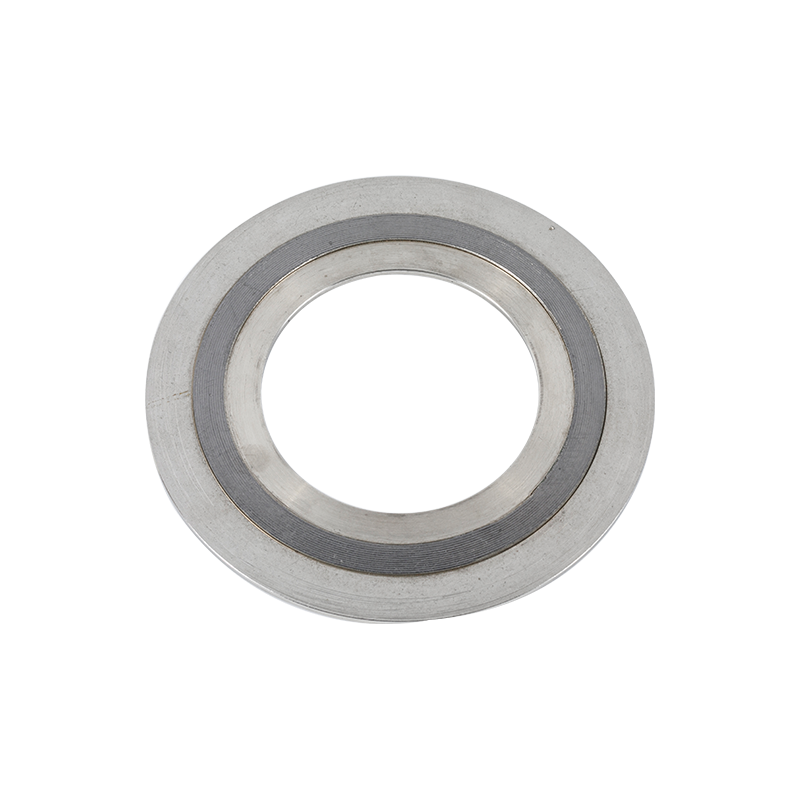

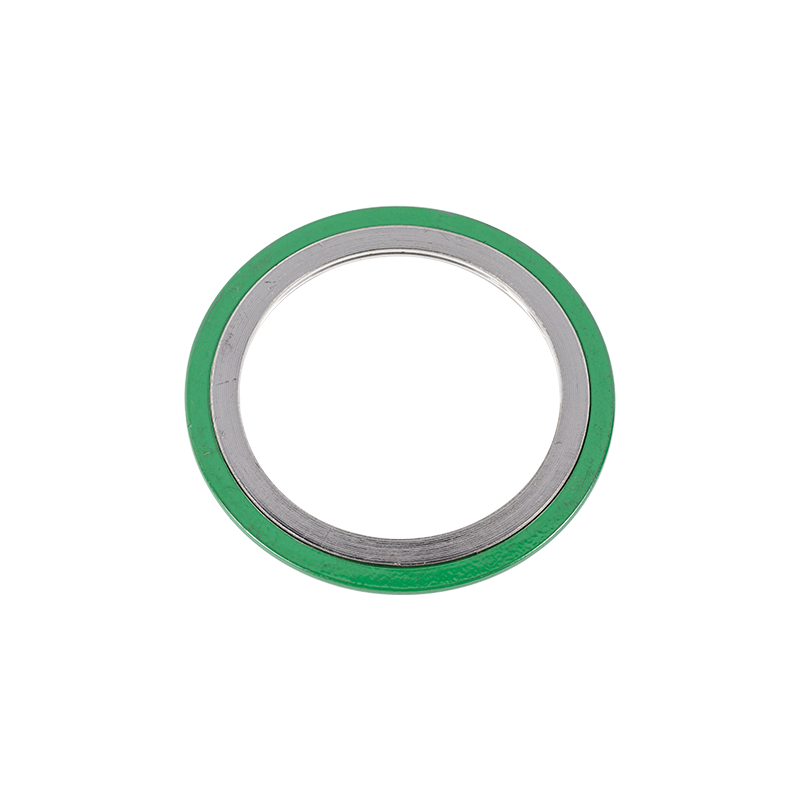

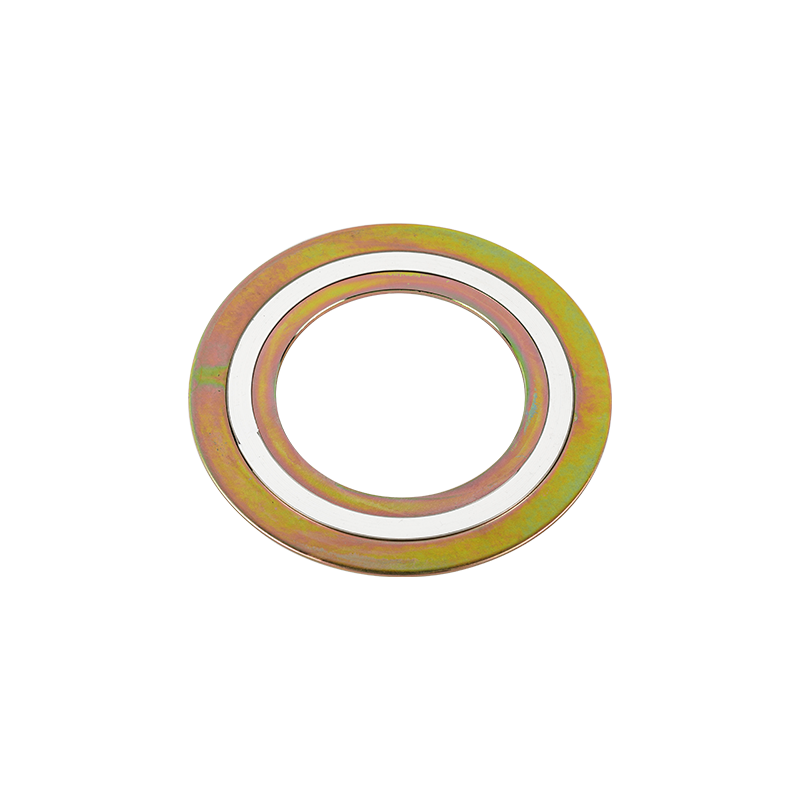

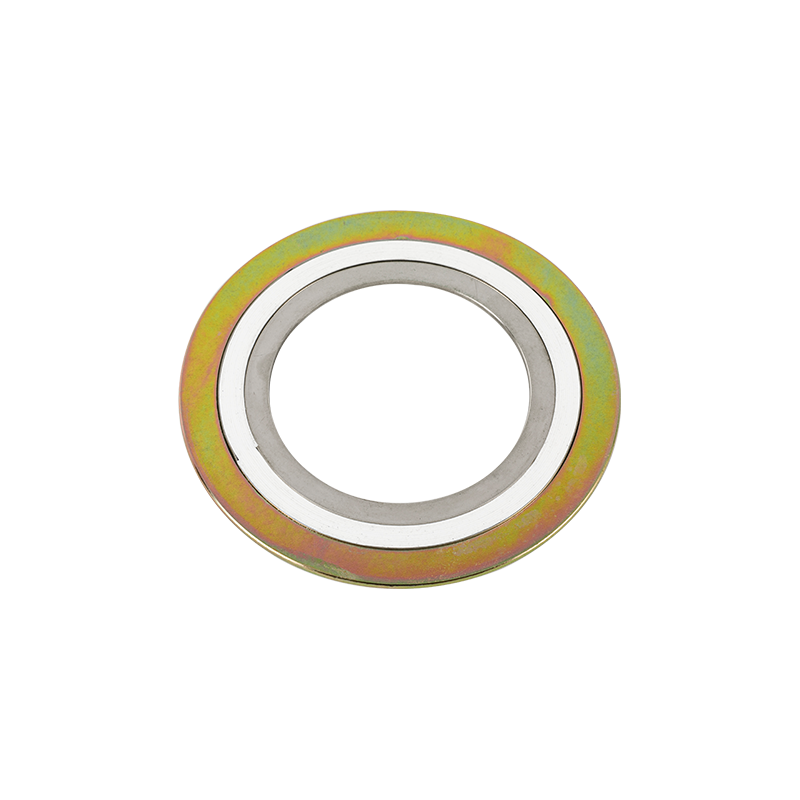

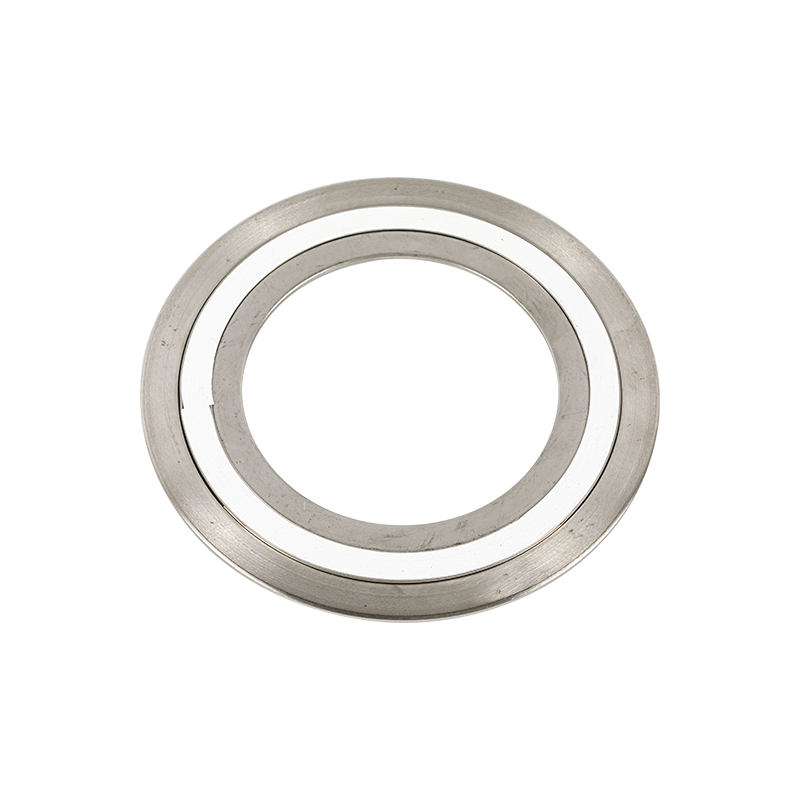

Spiral wound gaskets are renowned for their exceptional sealing performance, even in the most demanding conditions. The unique construction of these gaskets consists of alternating layers of metal and filler material, typically graphite or PTFE. This design creates a strong and tight seal that effectively prevents leaks, even under high temperature, pressure, or corrosive environments. The combination of the metal and filler materials ensures optimum compression and resilience, making spiral wound gaskets highly effective in achieving a reliable and long-lasting seal.

One of the key advantages of spiral wound gaskets is their versatility in adapting to different applications. These gaskets are available in a wide range of sizes, materials, and configurations, allowing them to be customized to meet specific requirements. Whether it is for flange connections, heat exchangers, pumps, or valves, spiral wound gaskets can be easily tailored to suit various industrial applications. This versatility ensures compatibility with different equipment, ensuring secure sealing across a multitude of systems and processes.

Spiral wound gaskets are engineered to withstand harsh operating conditions and provide long-lasting performance. The use of high-quality materials, such as stainless steel for the metal winding and flexible graphite or PTFE for the filler material, ensures excellent durability and resilience. These gaskets exhibit resistance to extreme temperatures, pressure, and chemical exposure, making them ideal for a wide range of industries, including oil and gas, petrochemical, power generation, and more. The robust construction of spiral wound gaskets ensures that they maintain their sealing integrity, even under challenging and dynamic environments.

Spiral wound gaskets are designed for easy installation and maintenance. Their flexible construction allows for simple compression and alignment during assembly, ensuring a proper fit. Additionally, spiral wound gaskets can be easily removed and replaced when necessary, thanks to their reliable and reusable design. This ease of installation and maintenance reduces downtime, increases operational efficiency, and minimizes costs associated with gasket replacement.

Spiral wound gaskets exhibit exceptional performance across a wide temperature and pressure range. Their ability to withstand extreme temperatures, ranging from cryogenic conditions to high-temperature applications, makes them suitable for various industrial processes. Additionally, spiral wound gaskets can effectively seal systems operating at high pressures, protecting against leaks and ensuring system integrity. This versatility and adaptability to different temperature and pressure conditions make spiral wound gaskets a preferred choice in industries where sealing performance is critical.

English

English

中文简体

中文简体