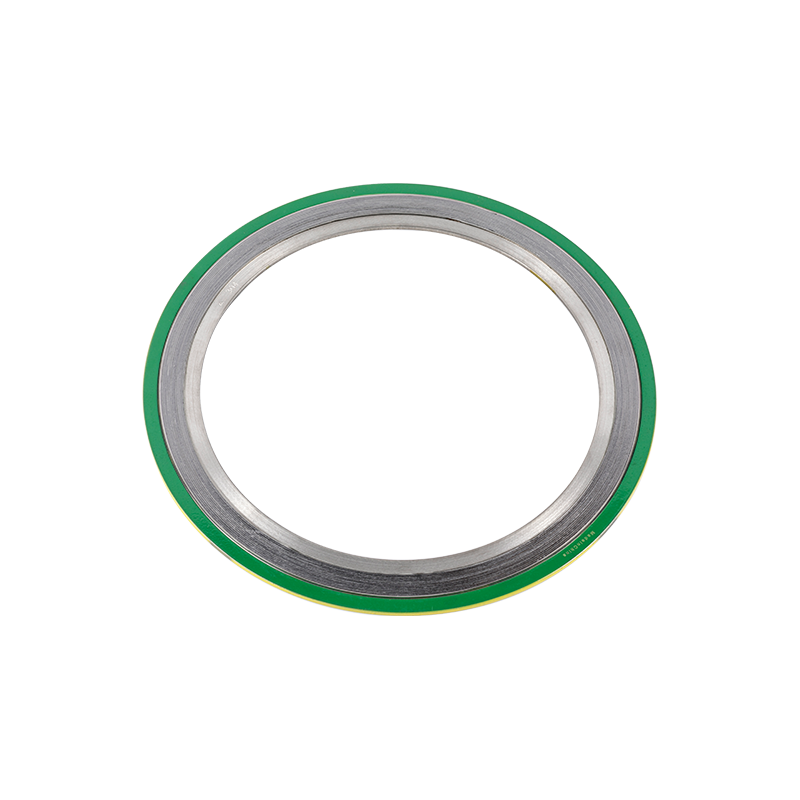

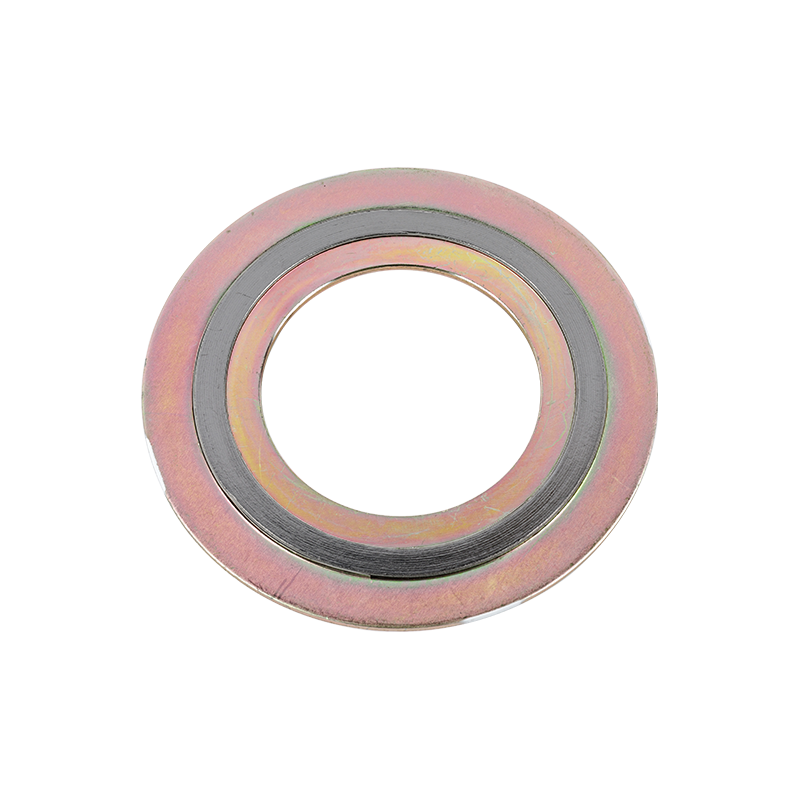

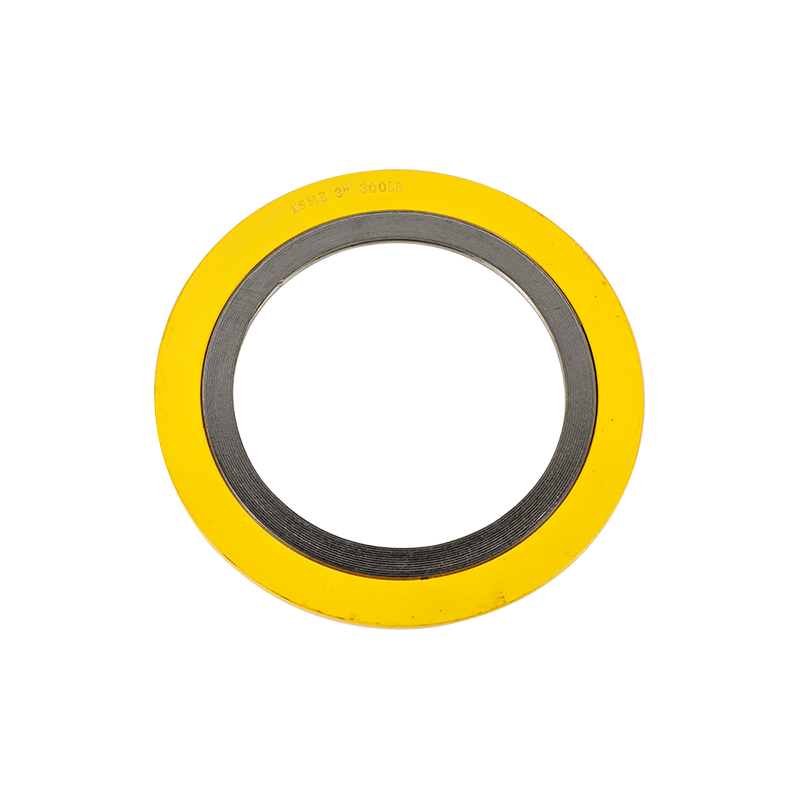

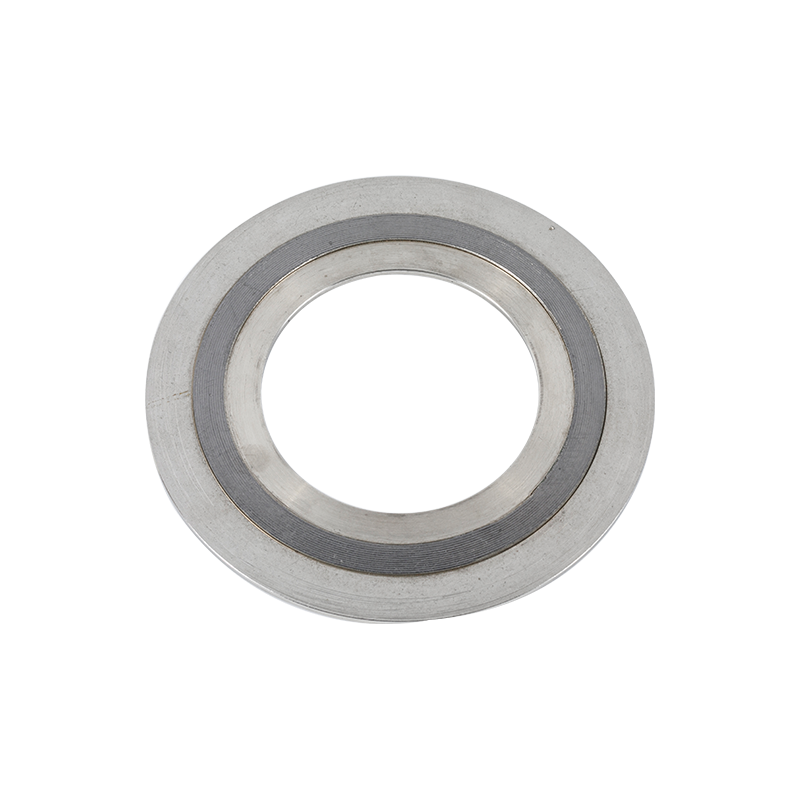

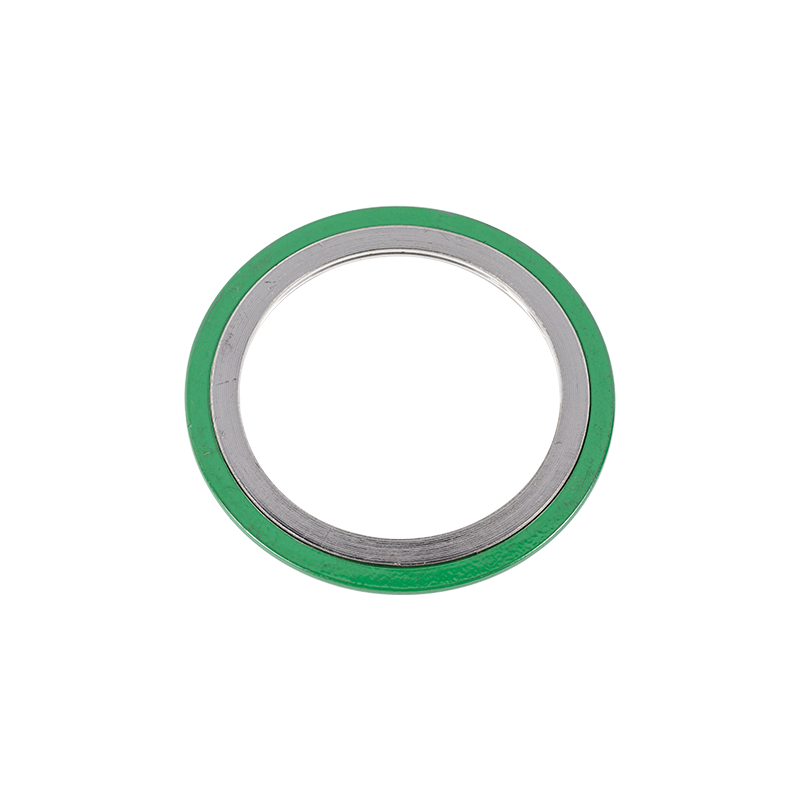

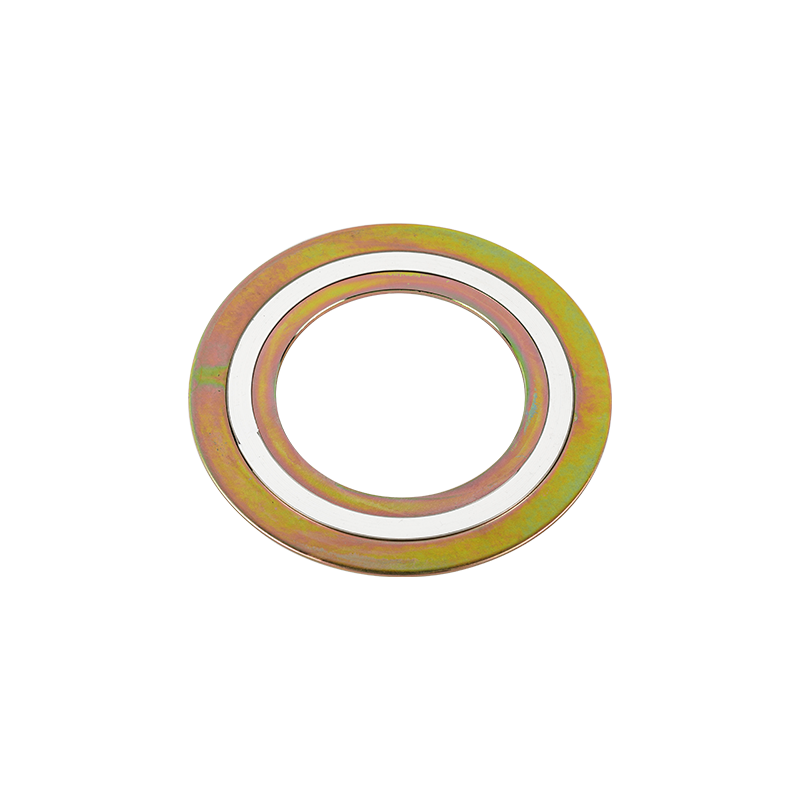

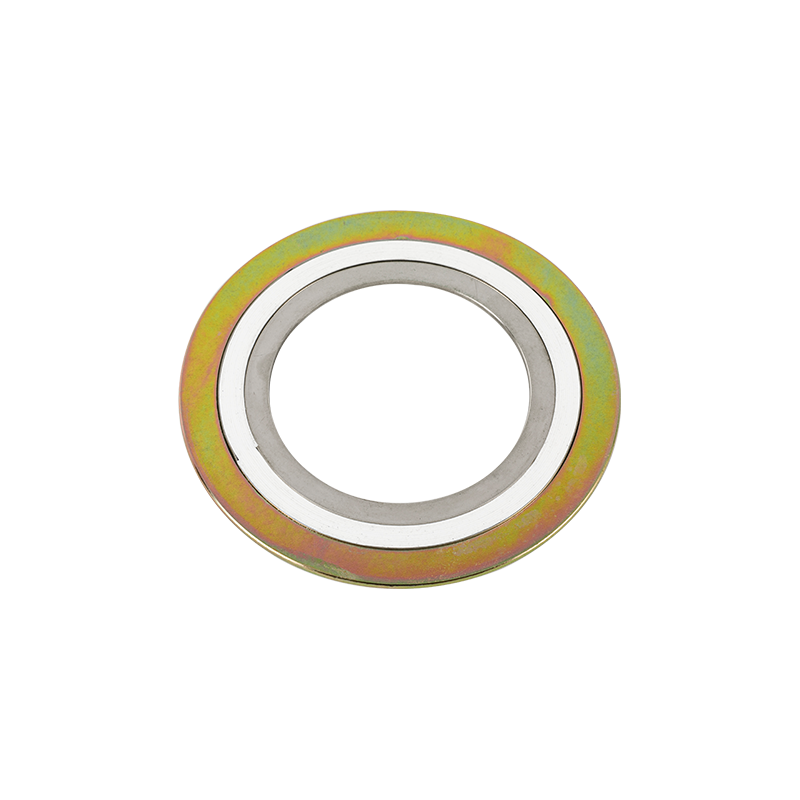

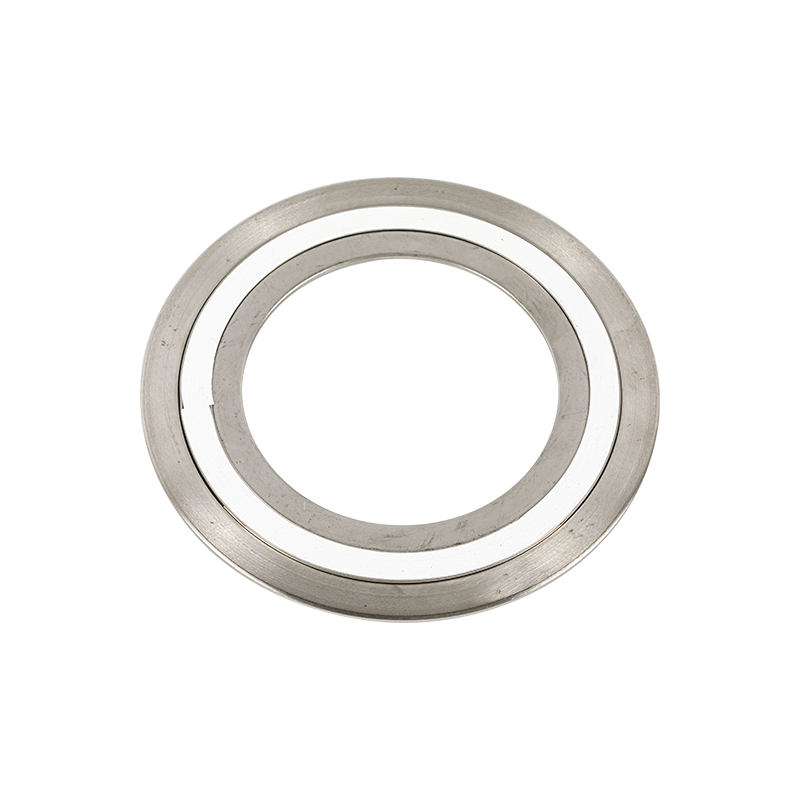

Spiral wound gaskets are commonly used in industrial applications for sealing purposes in pipelines, vessels, and other equipment. They are composed of several layers of materials that work together to provide an effective and reliable seal. The key components of a spiral wound gasket include:

1. Inner Ring: The innermost layer of a spiral wound gasket is typically a solid metal ring, which provides stability and reinforcement to the gasket. It helps to prevent inward buckling and maintains the gasket's shape during installation and operation.

2. Filler Material: The filler material is the core component of the gasket and is located between the inner and outer metal rings. It is typically made of a compressible material such as graphite, PTFE (polytetrafluoroethylene), or other flexible materials. The filler material acts as a sealing element and provides resilience to the gasket, allowing it to conform to irregularities on the sealing surfaces.

3. V-Shaped or W-Shaped Metal Strip: The filler material is held in place by a V-shaped or W-shaped metal strip, which is wound in a spiral pattern around the filler. This metal strip can be made of various materials, such as stainless steel or other alloys, and provides mechanical strength and structural integrity to the gasket.

4. Outer Ring: The outer ring is the outermost layer of the spiral wound gasket and acts as a compression limiter. It prevents over-compression of the gasket and helps to distribute the compressive forces evenly across the sealing surface, ensuring a proper seal. The outer ring is usually made of metal and can be solid or perforated.

The combination of these layers in a spiral wound gasket allows it to withstand high temperatures, pressures, and aggressive media. The compressible filler material accommodates flange irregularities, while the metal components provide strength, stability, and sealing capability. This construction enables spiral wound gaskets to effectively seal joints in various industrial applications.

English

English

中文简体

中文简体