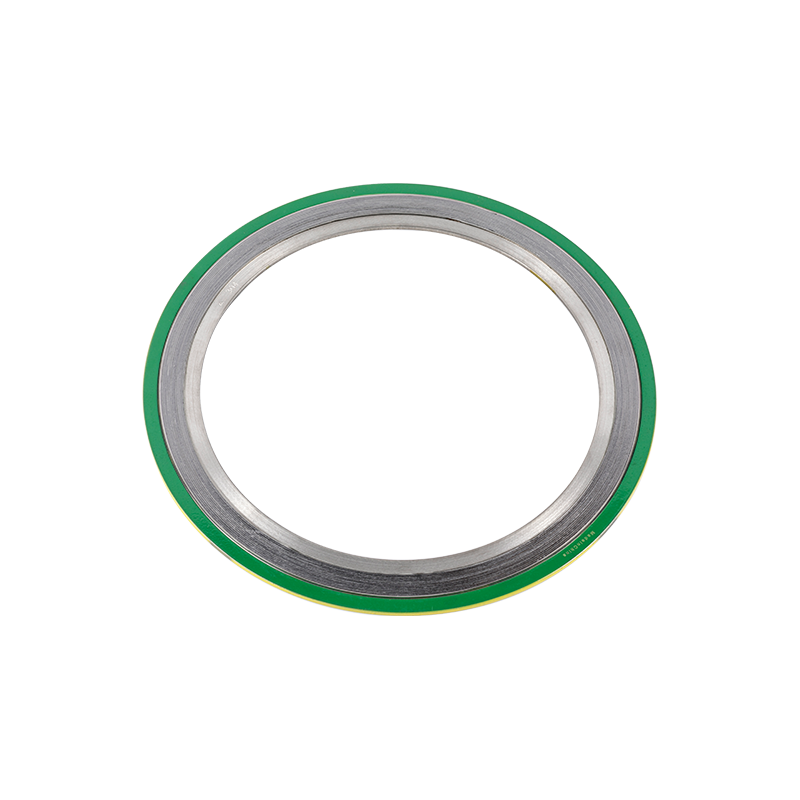

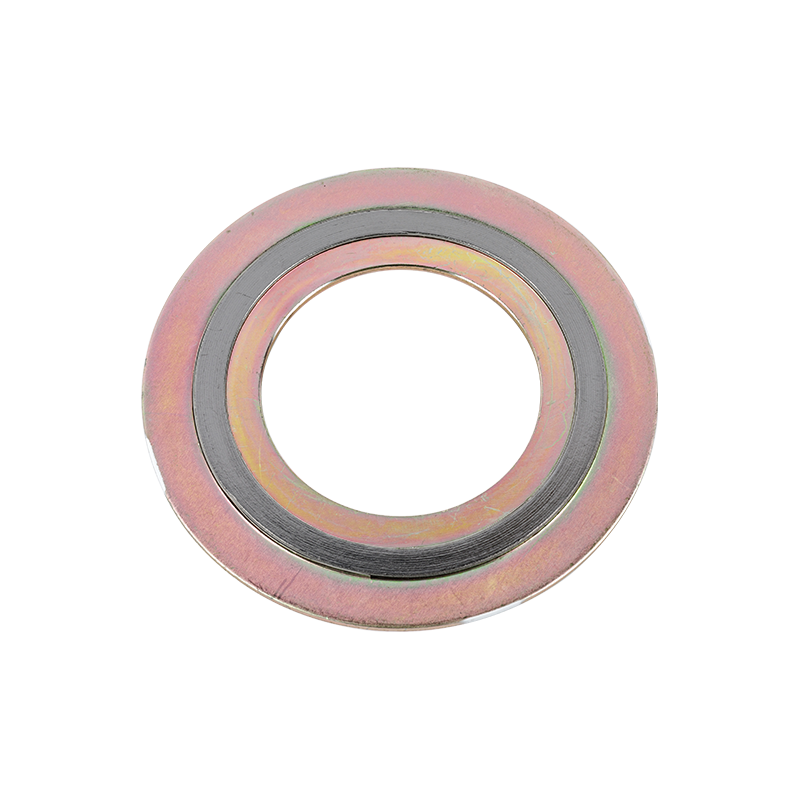

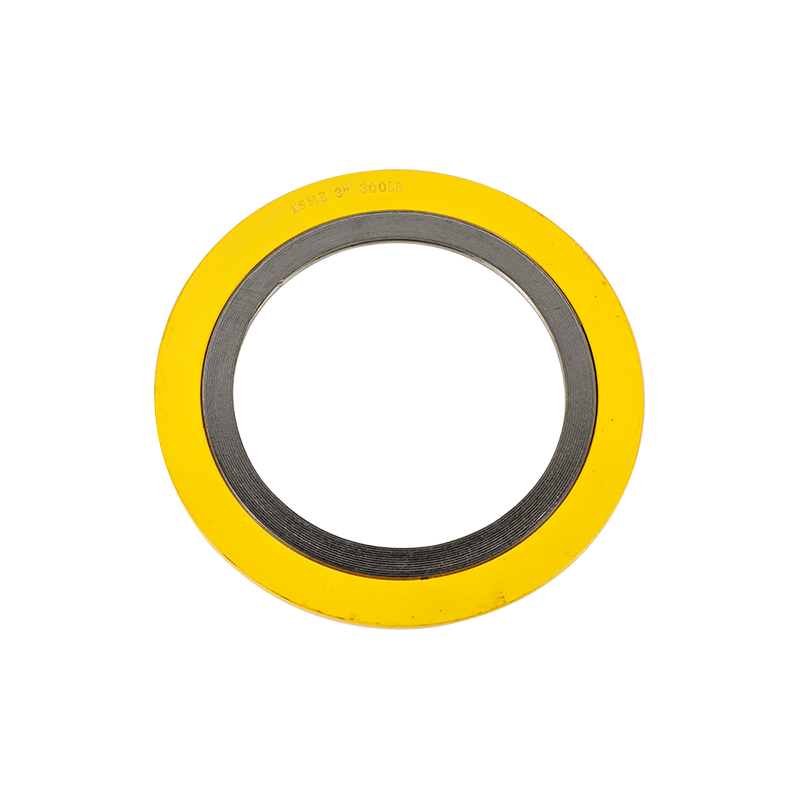

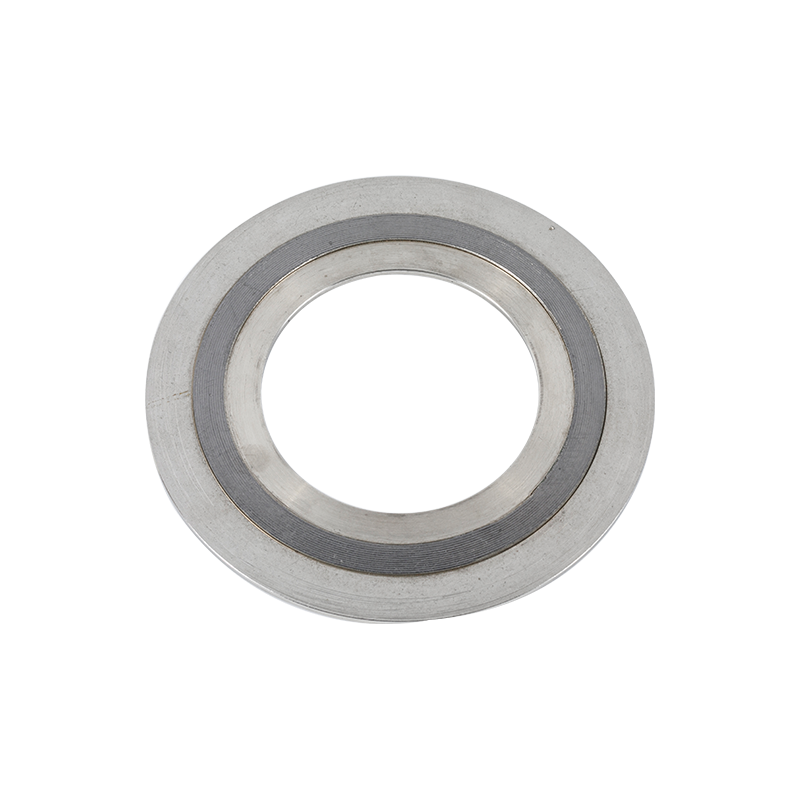

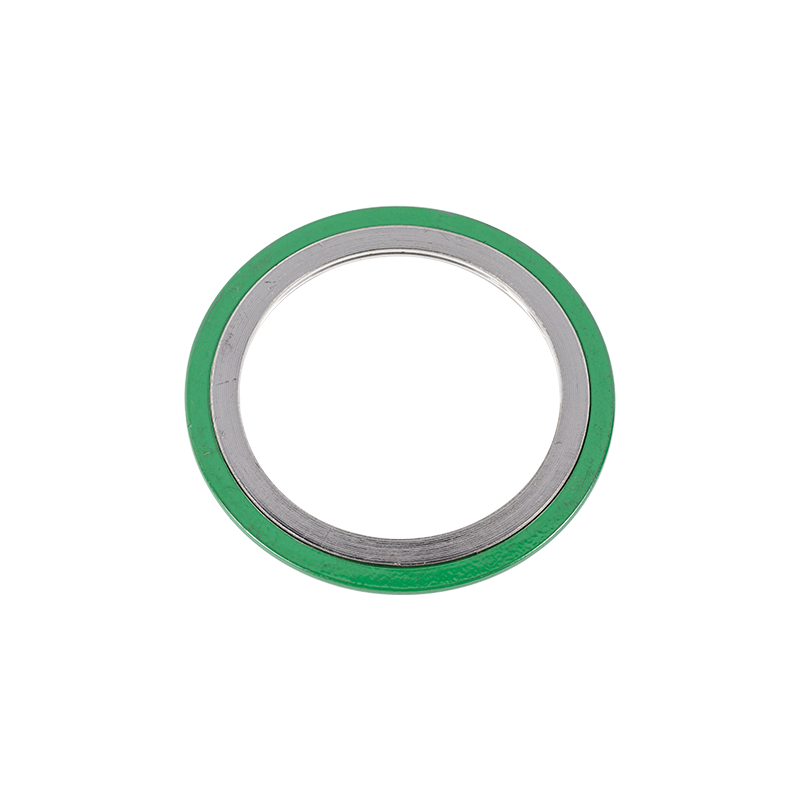

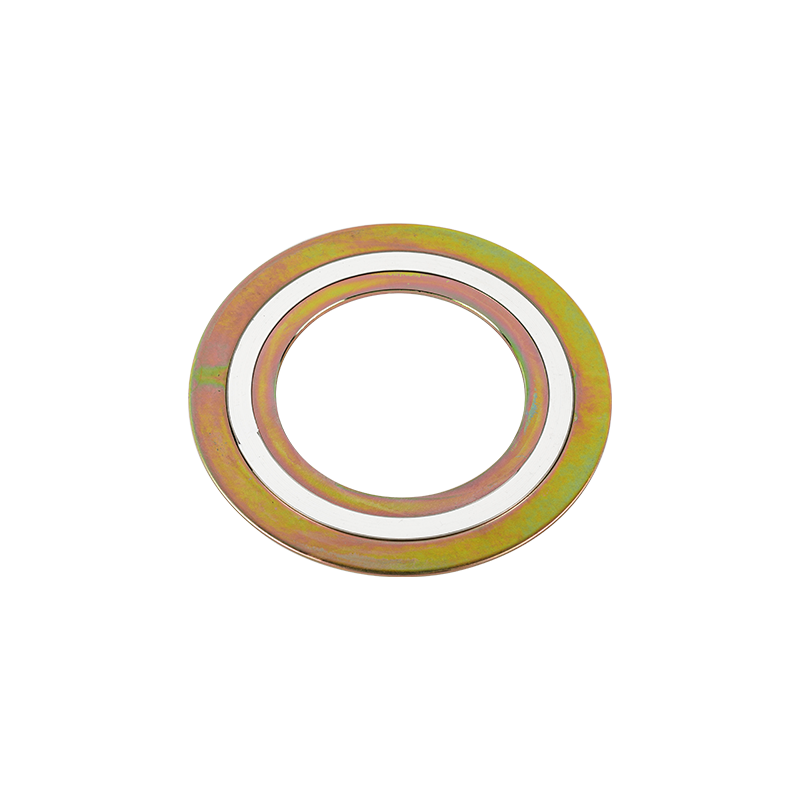

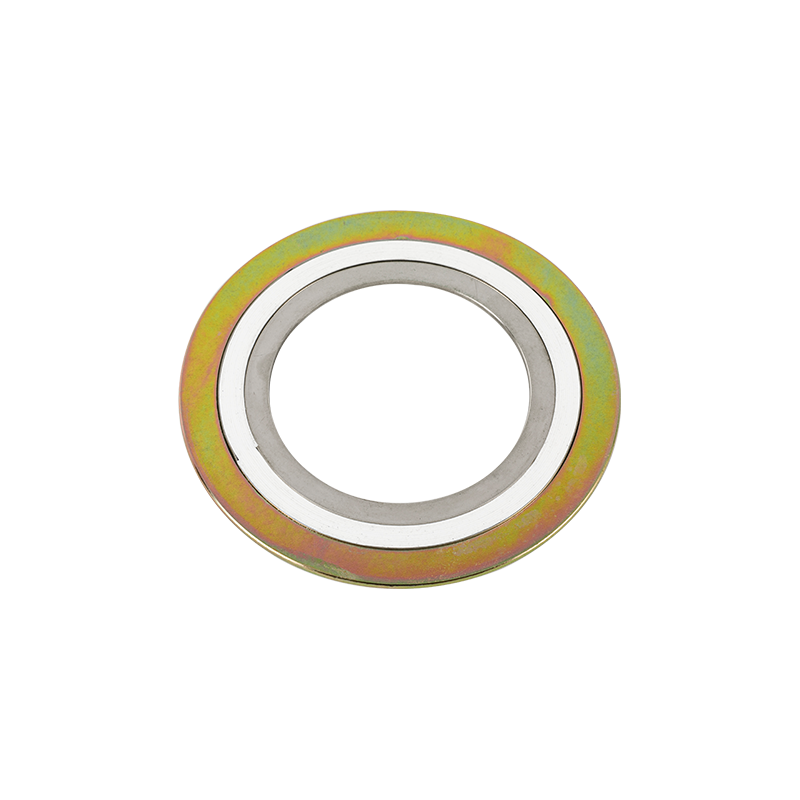

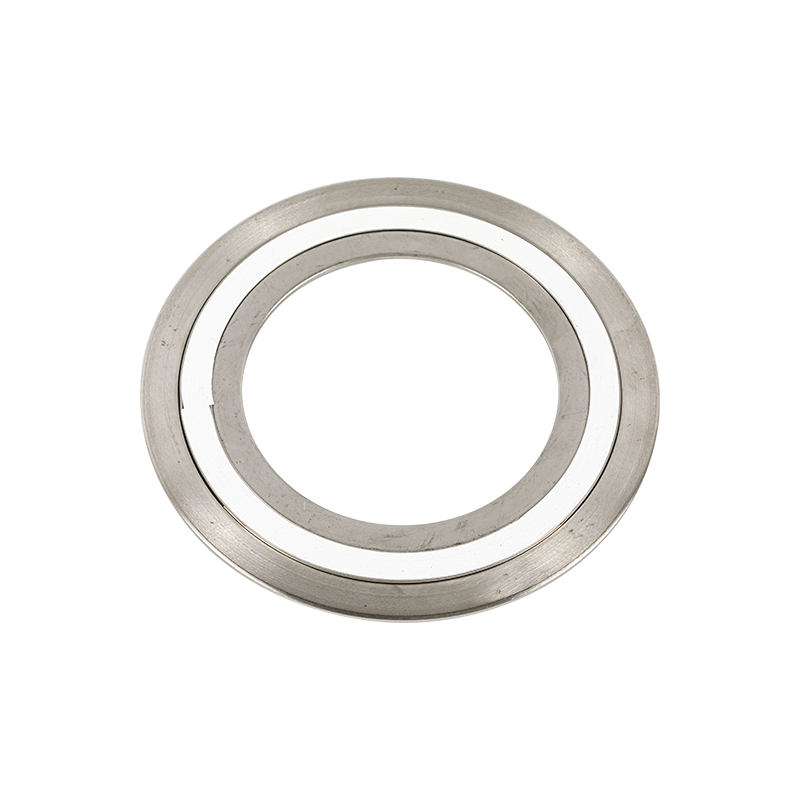

For the most demanding applications, we offer an inner ring (or ring for short) as an integral part of a gasket seal. Unlike conventional gaskets that are manufactured from a variety of materials - including cloth, foam, and paper - these seals are engineered to withstand exceptionally large assembly loads over a small area.

Inner Ring for SWG is a product for high pressure, high temperature, and/or highly corrosive applications. Unlike conventional gaskets that are manufactured from a variety of materials, this seal is engineered to withstand exceptionally large assembly loads over a small area. It is composed of proprietary material that creates uniform seal characteristics throughout the entire ring length.

Typically, they are made from solid metals including mild carbon steel or stainless steel. Some specialized varieties are available in specialty alloys such as Inconel or Titanium.Depending on the application, they can be custom tailored to your specific requirements.Aside from displaying the highest quality and performing a top notch job, these seals are functional, economical and environmentally friendly.The main function of an inner ring is to help center the sealing element into the proper position within the pipe bore, preventing windings from buckling or deforming over time.

The ring is also designed to reduce flange erosion and prevent debris from accumulating in the media or gasket cavity.The ring is usually supplied in one of four sizes from 2" to 24". It's also possible to get the ring in a smaller diameter for your specific application.There is no shortage of gasket manufacturers to choose from, but KXT is your best bet for the quality and performance that you can count on.

English

English

中文简体

中文简体