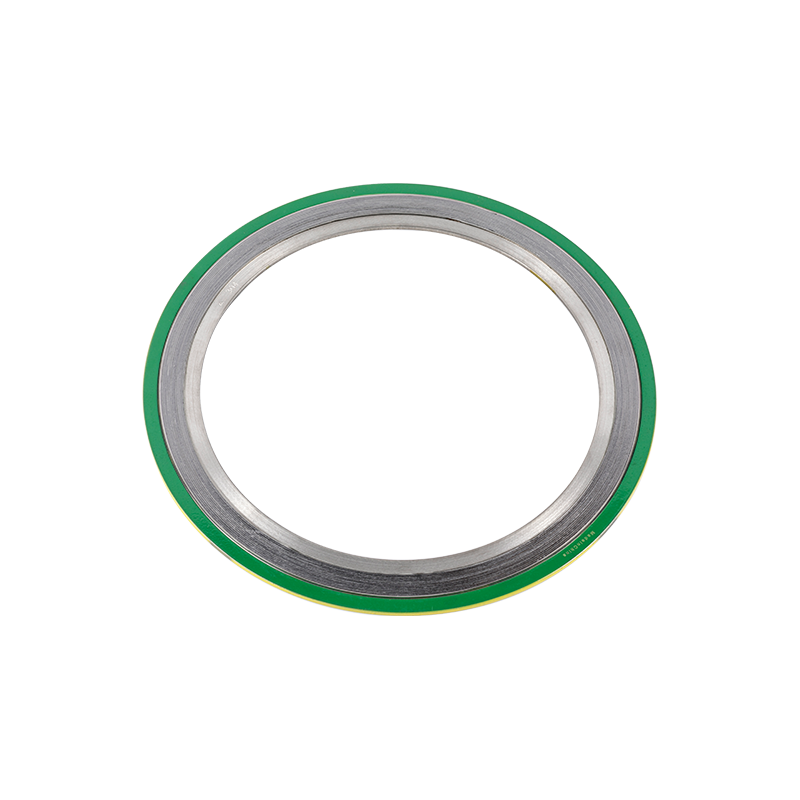

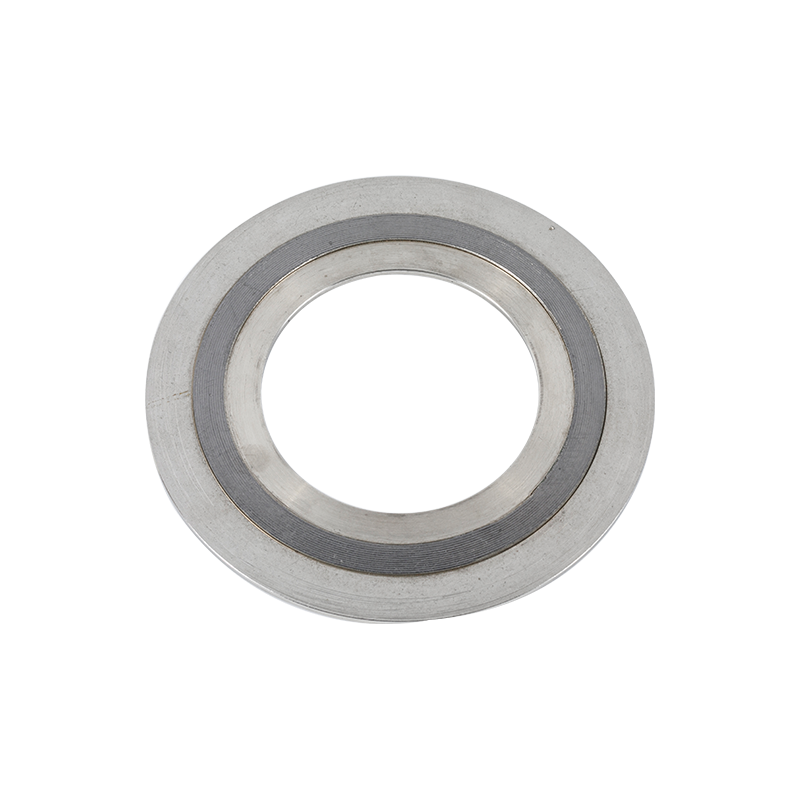

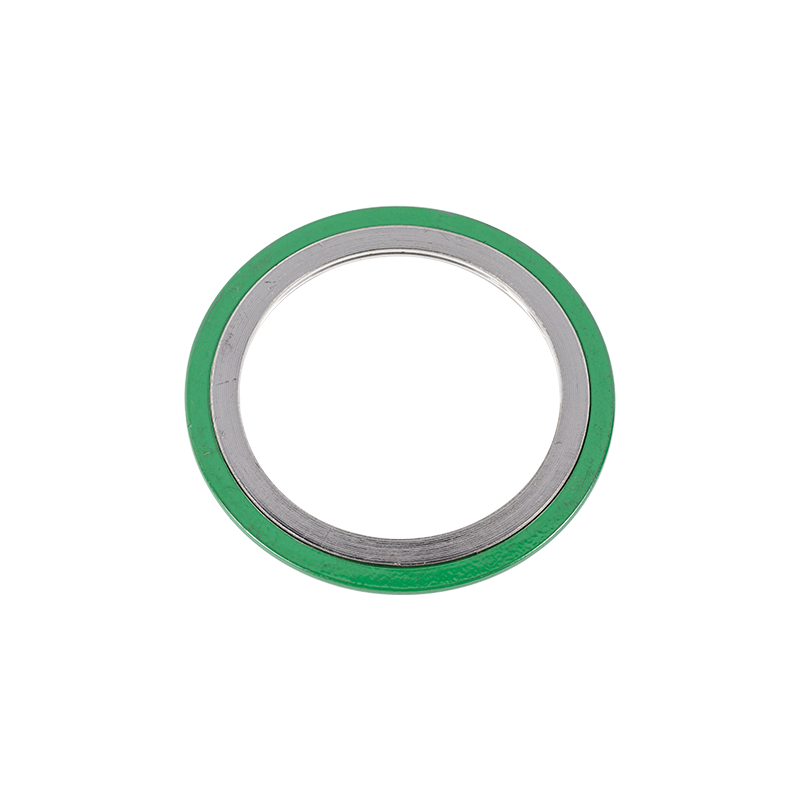

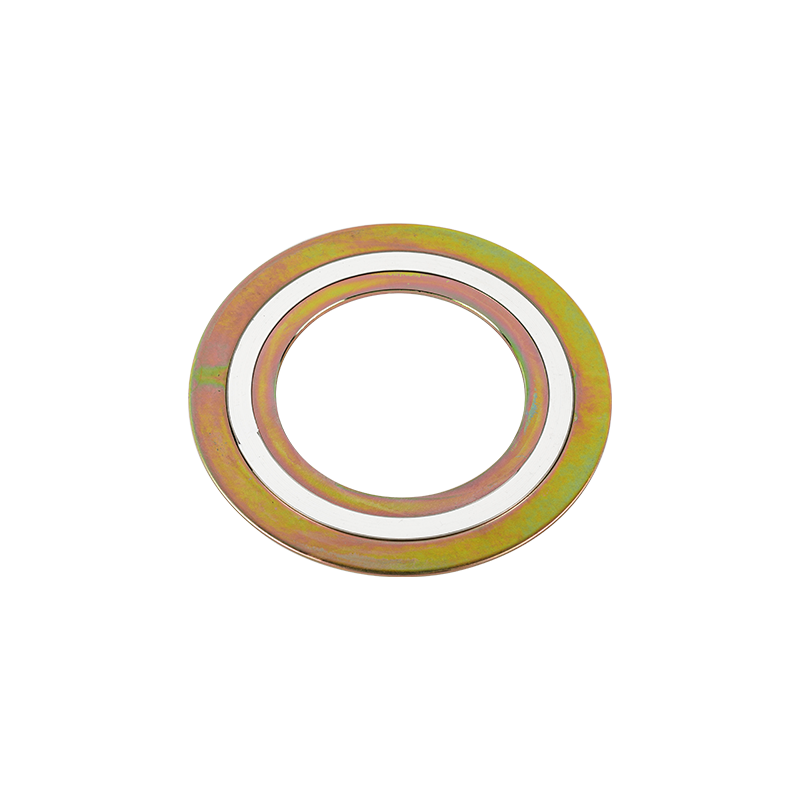

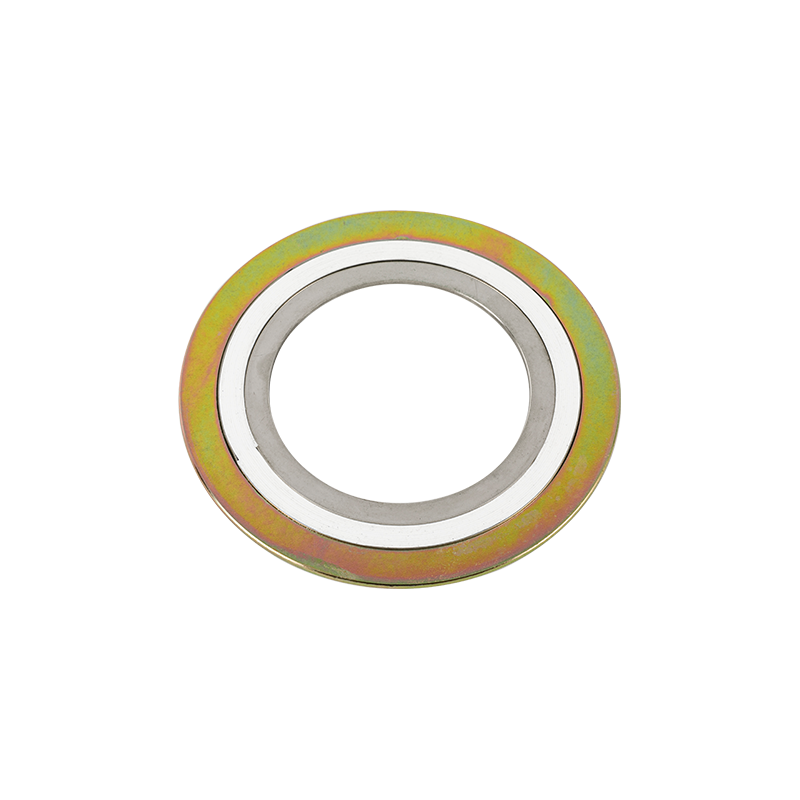

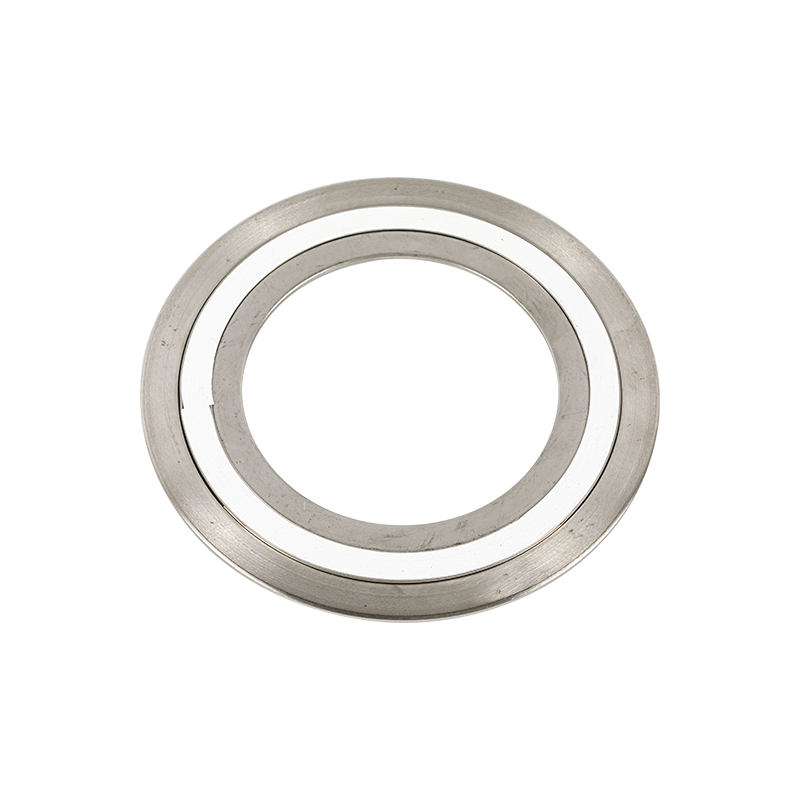

Spiral wound gaskets are commonly used in machines for sealing applications, particularly in high-temperature and high-pressure environments. Some of the benefits of using spiral wound gaskets include:

Good Sealing Performance: Spiral wound gaskets offer excellent sealing performance due to their design. They are made up of alternating layers of metal and filler material, which enables them to seal effectively even in high-pressure and high-temperature applications.

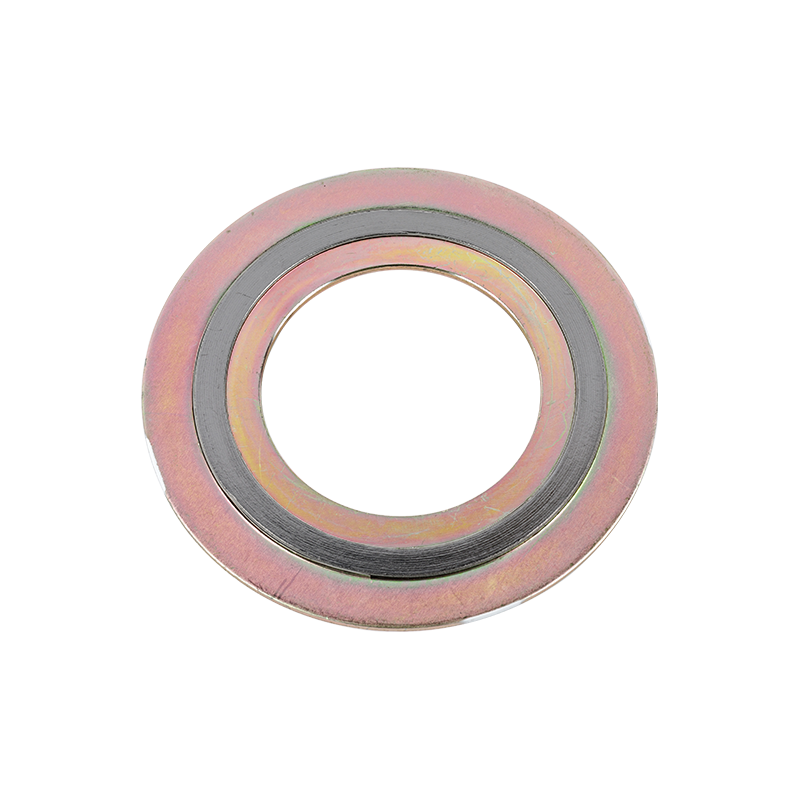

Versatility: Spiral wound gaskets can be used in a wide range of applications, including petrochemical, chemical, and refining industries. They are also suitable for use in flanges, heat exchangers, valves, and pumps.

Resilience: Spiral wound gaskets are designed to withstand extreme conditions, including high-pressure, high-temperature, and corrosive environments. They can maintain their sealing performance over a long period, reducing the need for frequent replacement.

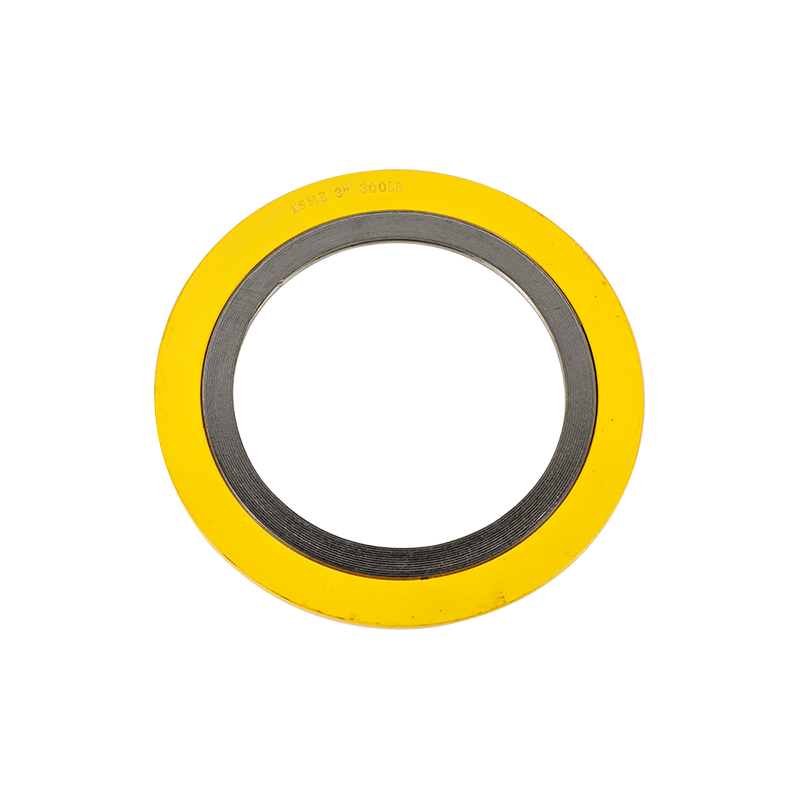

Cost-effective: Spiral wound gaskets offer a cost-effective solution for sealing applications. They are more durable than other types of gaskets and require less frequent replacement, reducing maintenance costs.

Easy Installation: Spiral wound gaskets are easy to install, making them an attractive option for applications that require quick installation and maintenance.

English

English

中文简体

中文简体