1. Types of gaskets

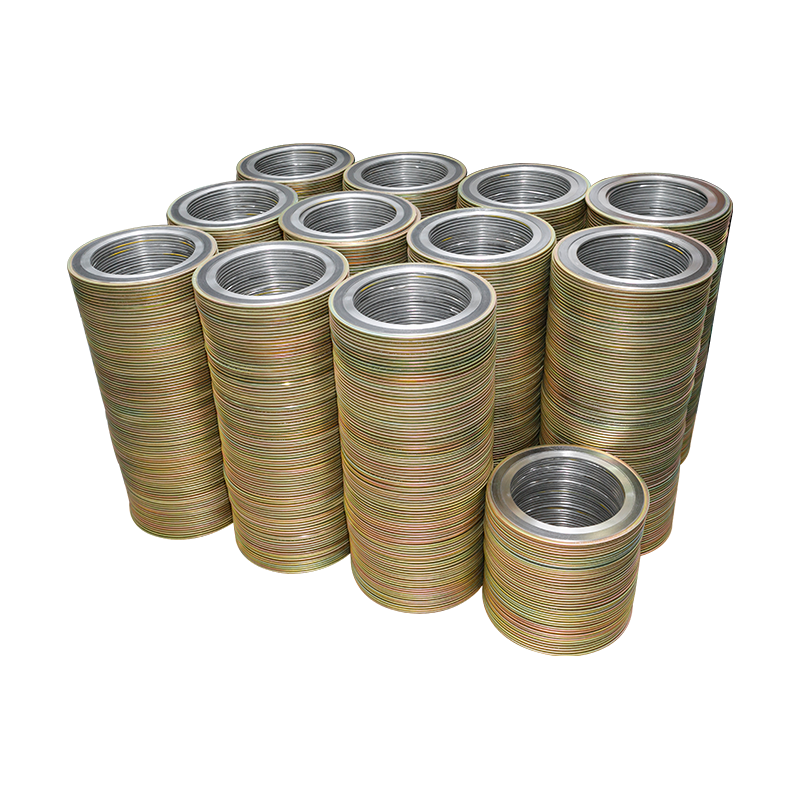

There are many kinds of Spiral Wound Gaskets manufacturer gaskets, which can be roughly divided into three categories according to their materials and structures.

The first category: non-metallic gaskets. Rubber, asbestos rubber sheet, flexible graphite, polytetrafluoroethylene, etc., the cross-sectional shape is all rectangular.

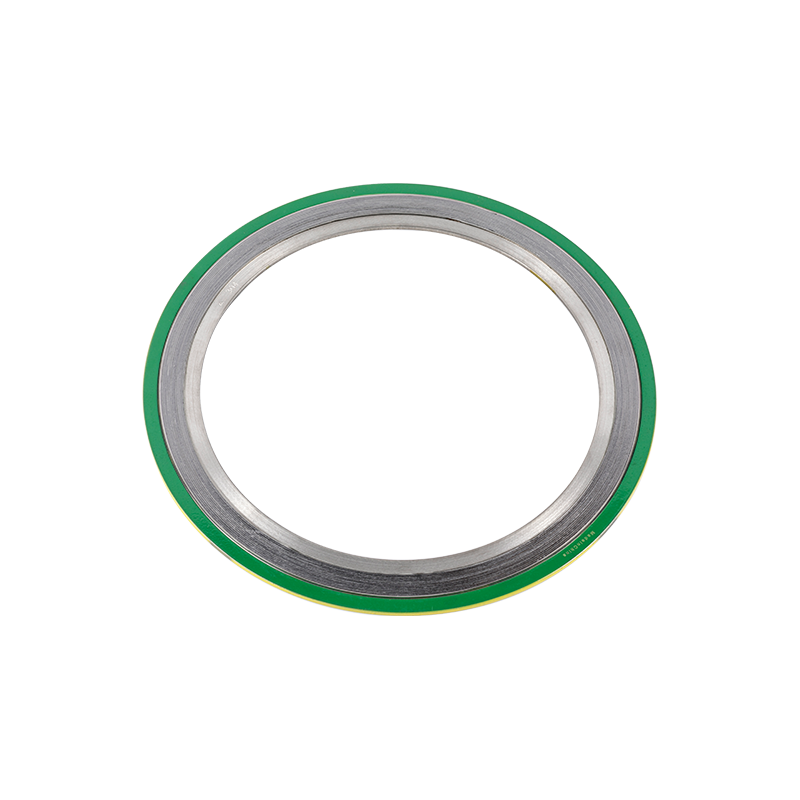

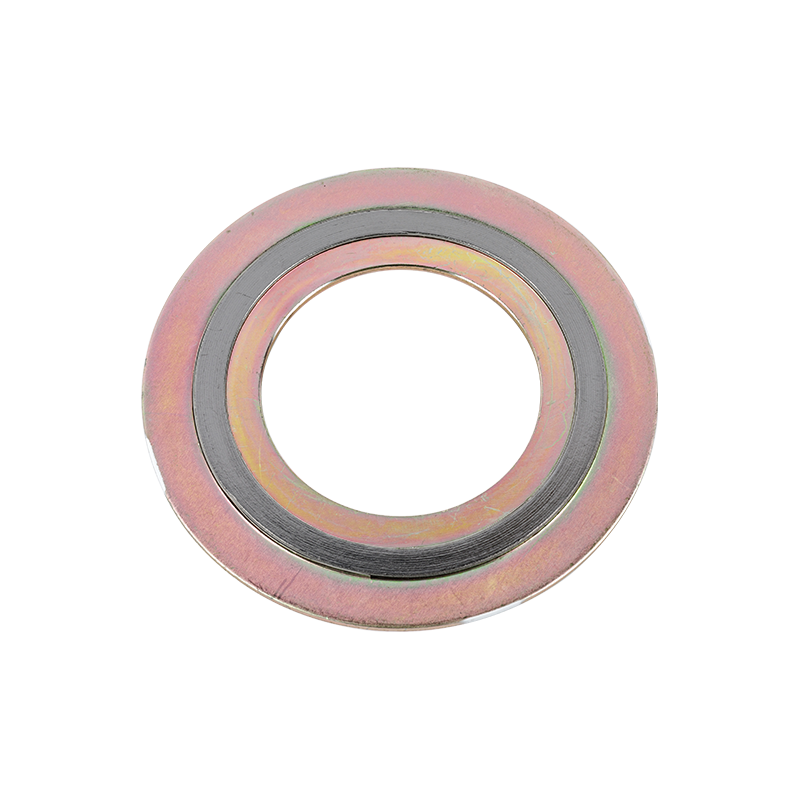

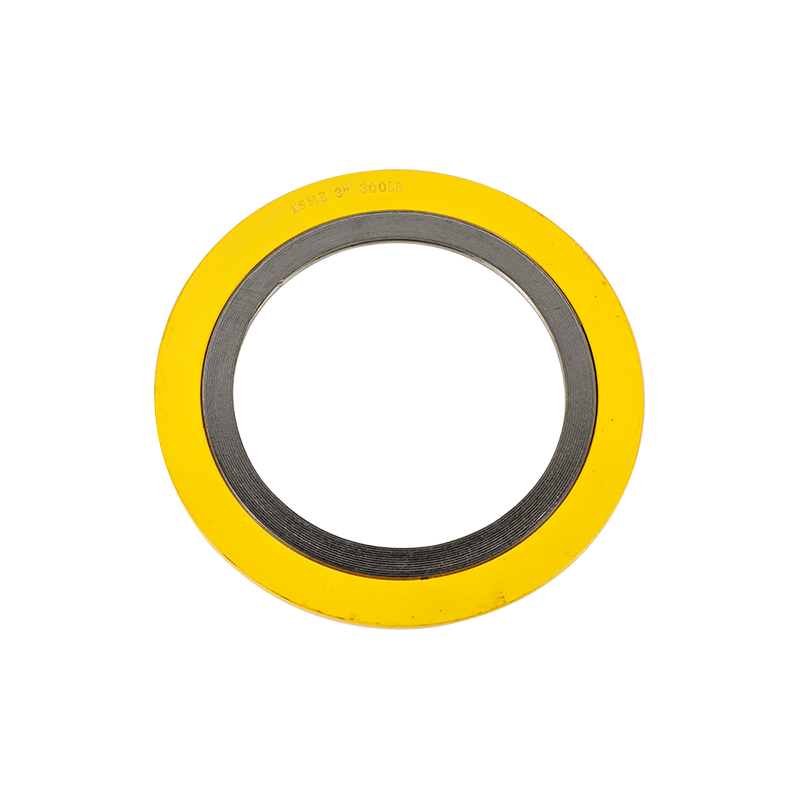

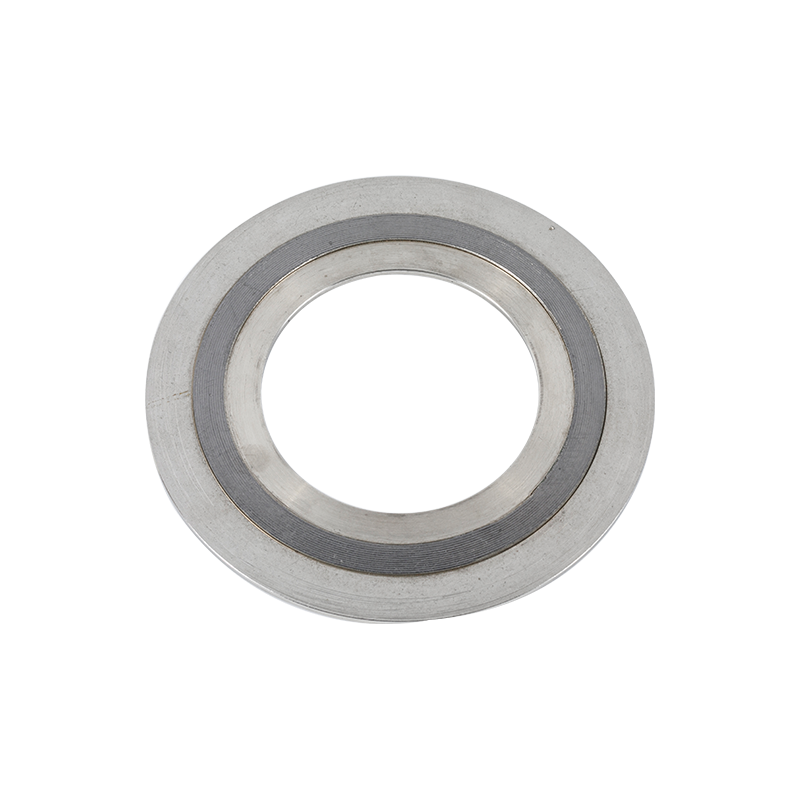

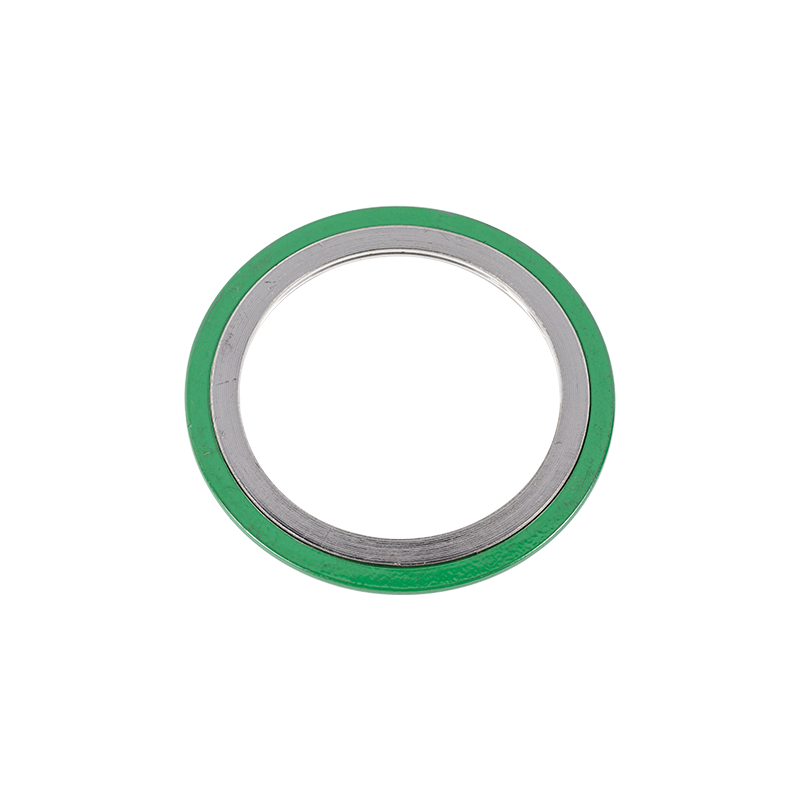

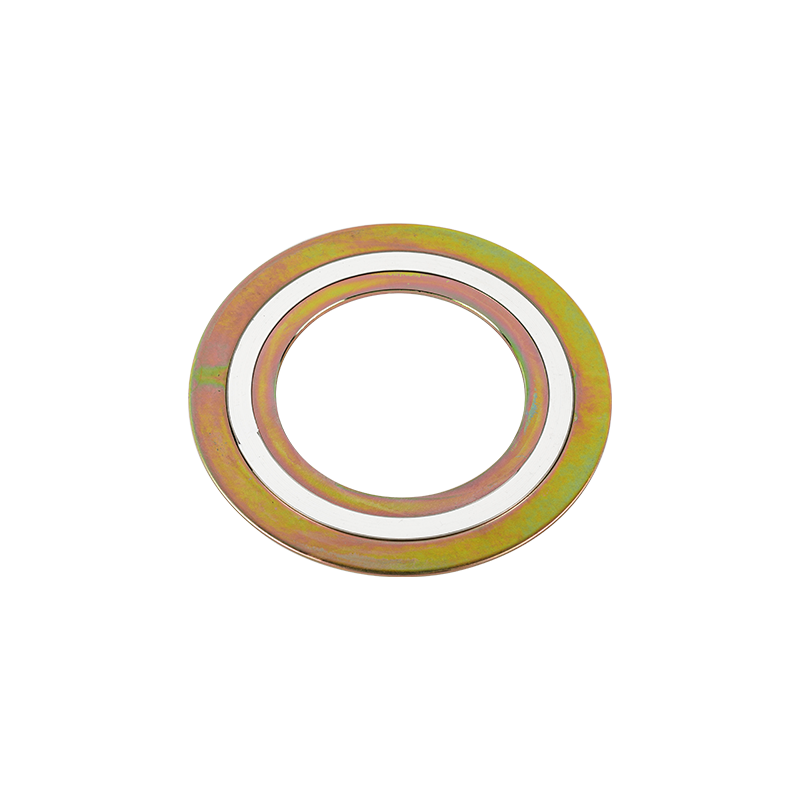

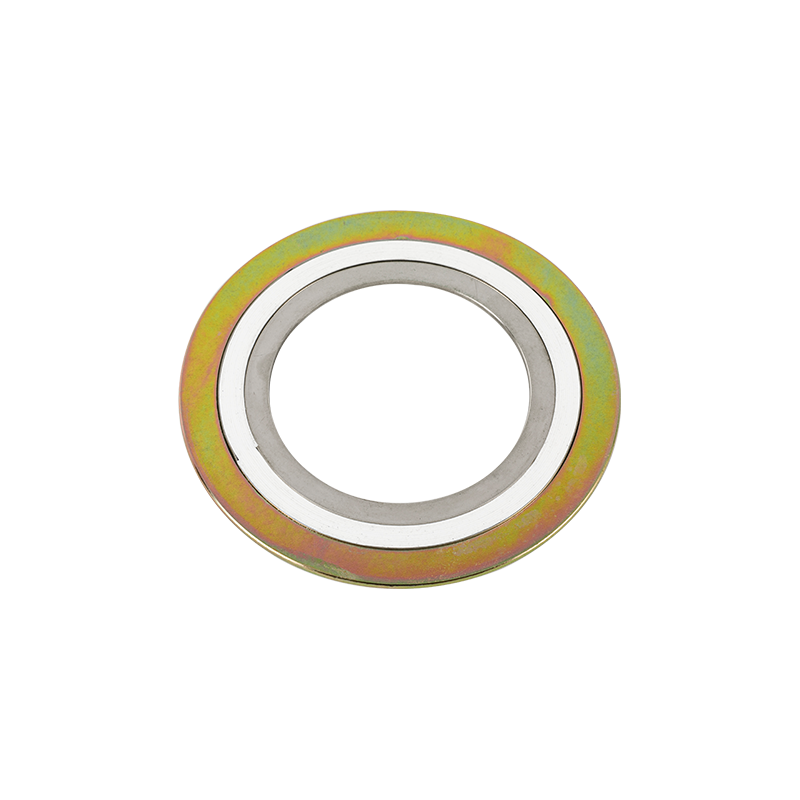

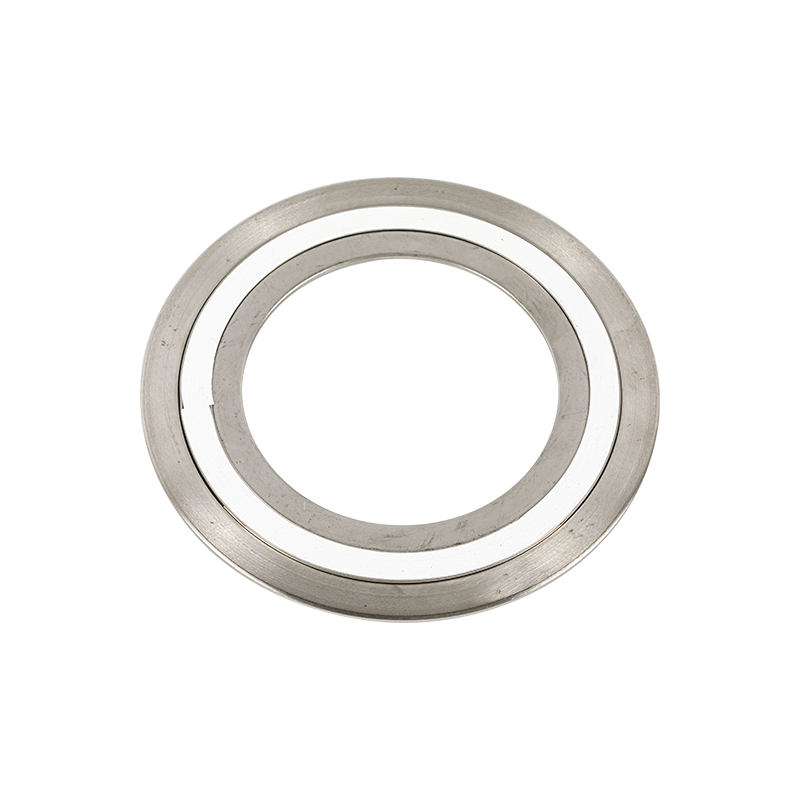

The second category: metal composite gaskets. Various metal pads, metal wound pads.

The third category: metal gaskets. There are metal flat pads, wave pads, ring pads, tooth pads, lens pads, triangular pads, double cone rings, C-rings, hollow O-rings, etc.

According to the principle of sealing classification, the first, second and third types of metal flat gaskets, corrugated gaskets, annular gaskets, toothed gaskets, and lens gaskets in the above gaskets belong to mandatory seals, while the rest are semi-self-tightening or self-tightening. tight seal.

2. Selection of gaskets

Correct selection of gaskets is the key to ensuring no leakage in pipeline engineering. For the same working condition, there are generally several kinds of gaskets to choose from. The gasket must be selected reasonably according to the physical properties, pressure, temperature and equipment size, operating conditions, and continuous operation cycle of the medium.

①. Selection principle of gasket

a. The following data should be known when selecting or ordering gaskets.

Matching flange sealing face form and size.

Flange and gasket nominal size.

Flange and gasket nominal pressure.

temperature of the fluid medium.

properties of the fluid medium.

b. The following factors should also be considered when selecting gaskets.

It has good compression and resilience performance and can adapt to fluctuations in temperature and pressure.

It has good plasticity and can fit well with the flange sealing surface.

For flanges of certain metals (such as austenitic stainless and acid-resistant steel) prone to stress corrosion cracking, it should be ensured that the gasket material does not contain excess impurities that may cause various corrosion, such as controlling the chloride ion content of the gasket to prevent damage to the gasket. Flange corrosion.

Do not pollute the medium (meaning that the sealing medium is drinking water, plasma, medicine, food, beer, etc.).

For sealing highly toxic chemicals, gaskets are required to have greater safety, and for pipeline systems transporting flammable liquids, gaskets are required to be used on flanges. The maximum operating pressure and maximum operating temperature are within the limits.

It is not easy to harden at low temperature, the shrinkage is small, and it is not easy to soften at high temperature, and has good creep resistance.

Good processing performance, easy installation and pressing.

Non-bonded flange sealing surface, easy to disassemble.

English

English

中文简体

中文简体