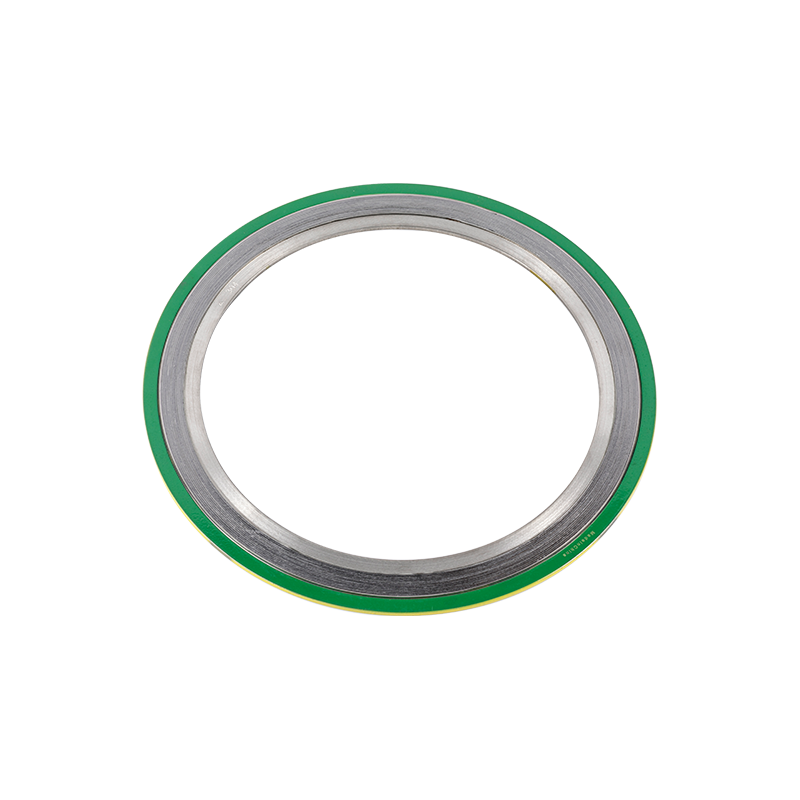

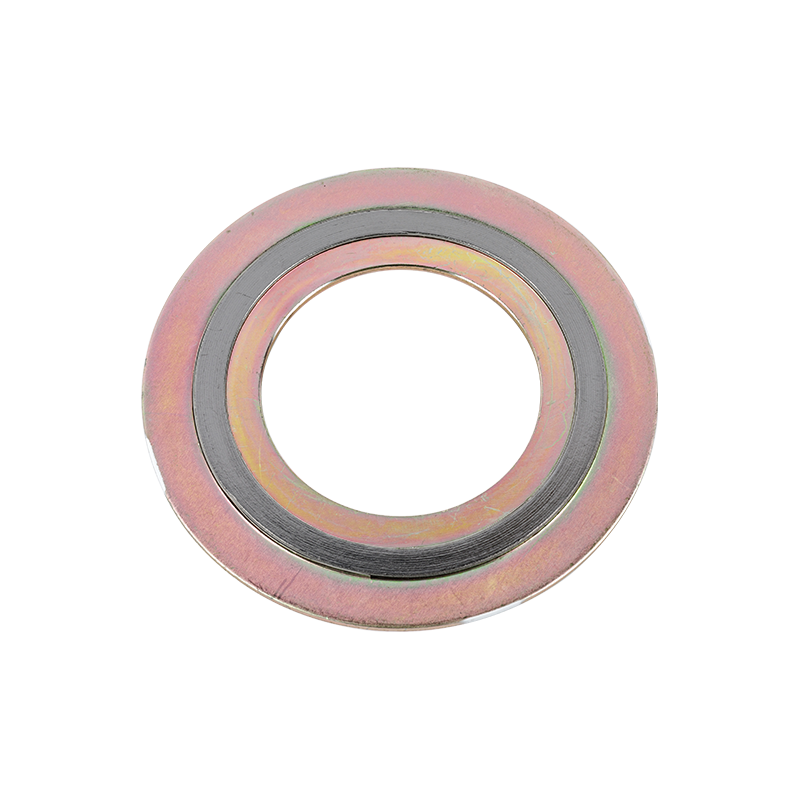

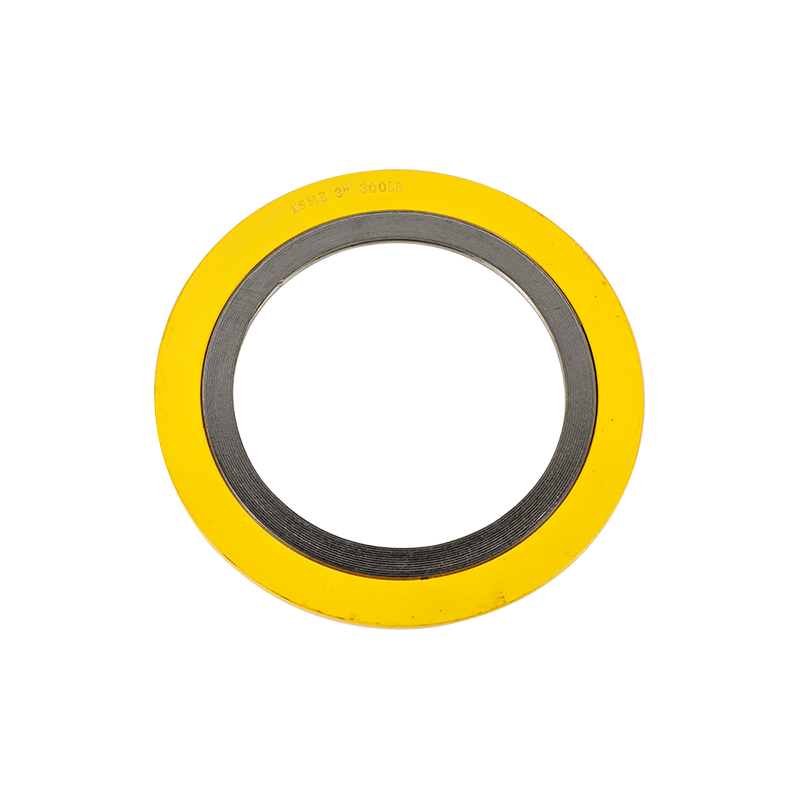

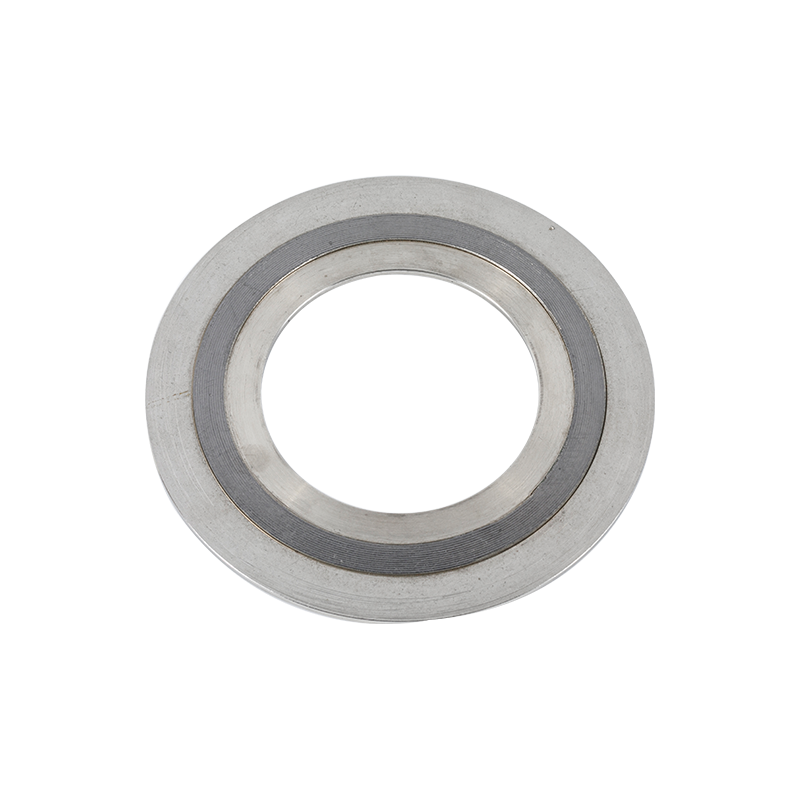

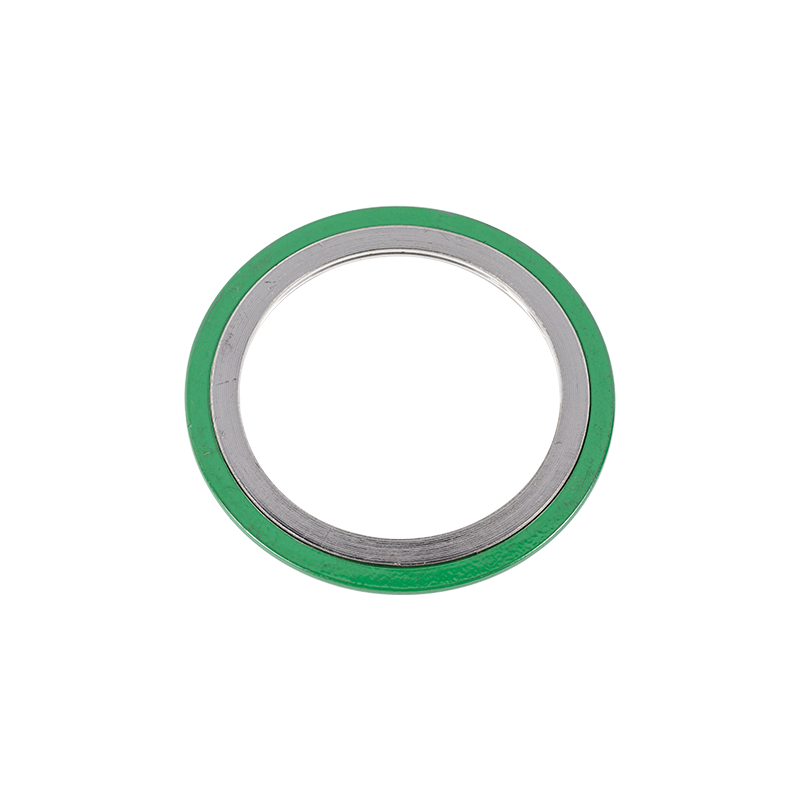

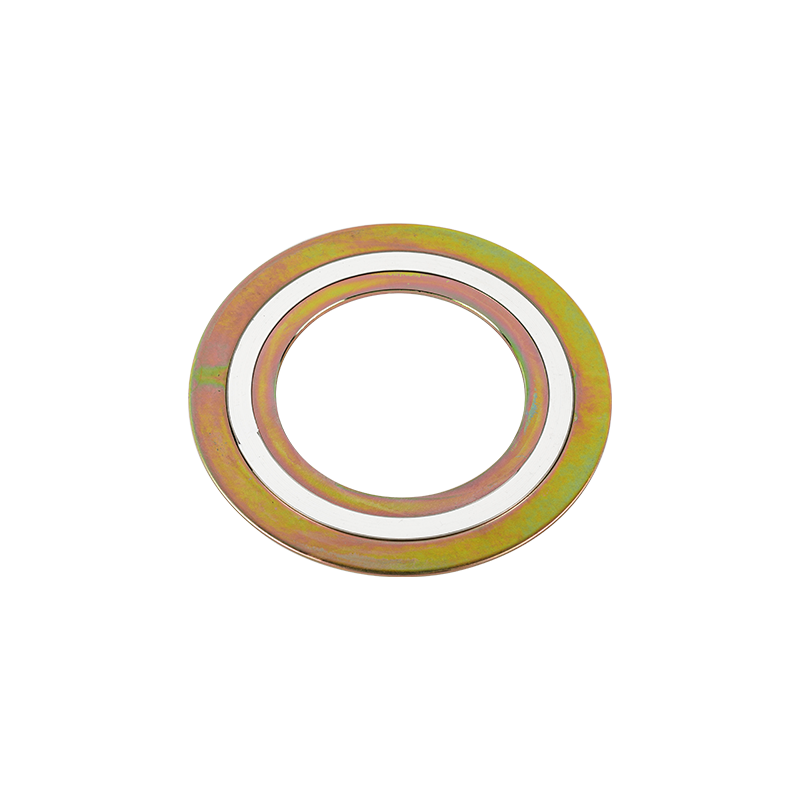

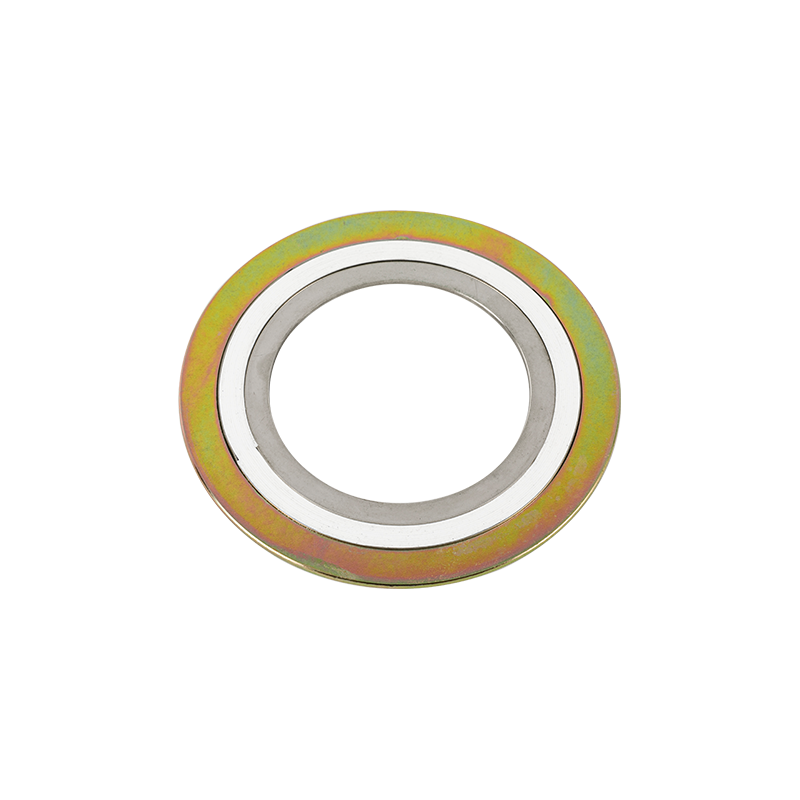

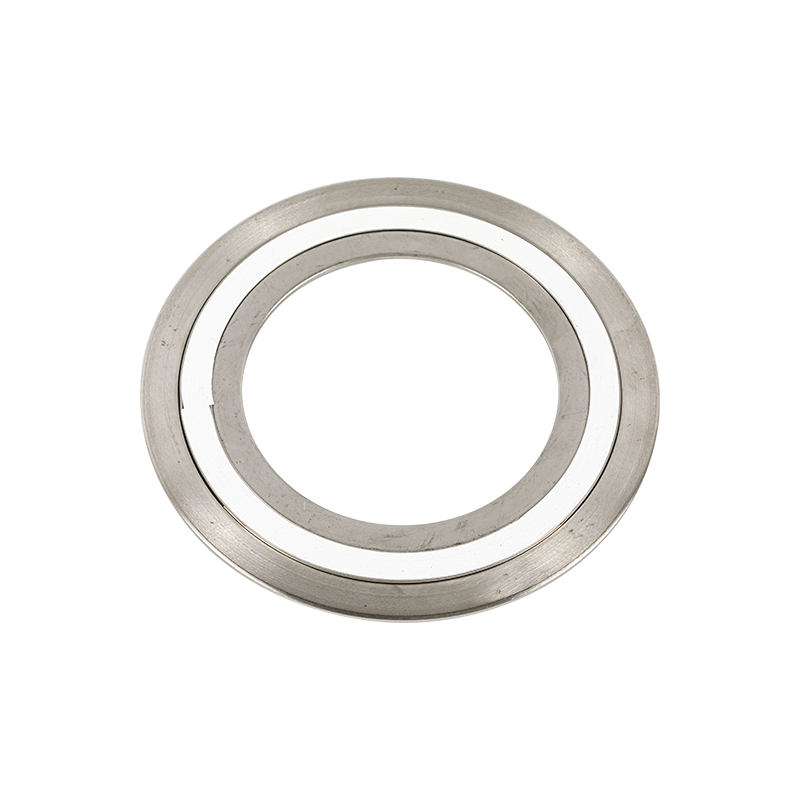

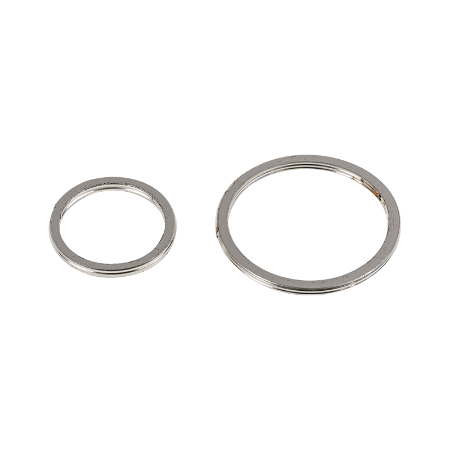

Exhaust Muffler Seal Rings are very important in keeping the exhaust system in good condition. The seal ring is a relatively inexpensive item that should be replaced after servicing the exhaust system.The sealing ring is composed of numerous metal wires. The resulting spherical sealing surface is a result of compressive molding of the wires. These wires are woven in a three-strand configuration. They are made from a material of sufficient hardness and durability to withstand high temperatures. The resulting spherical shape has an approximate diameter of 0.009 inches.

Generally, the sealing ring is used for joint connections in flexible intermediated elements such as exhaust headers and mufflers. These intermediated elements have very strict temperature requirements. Consequently, the ring must have a very robust sealing surface.The ring is manufactured using a special compressed knitted wire mesh that is coated with mica or graphite. The composite sealing ring is made up of a matrix of 85% stainless steel and 15% mica. It is a relatively homogeneous structure. The ring can also be made up of a number of layers.

The sealing ring may also include a spherical surface for sealing the manifold outlet. This surface maintains gas sealing relationship between the manifold and header and also prevents leakage of the exhaust gases. It can be created through compressive molding of wires or through close packing. It is also capable of sustaining considerable abrasive rubbing. The result is a spherical seal that is wear resistant.

English

English

中文简体

中文简体