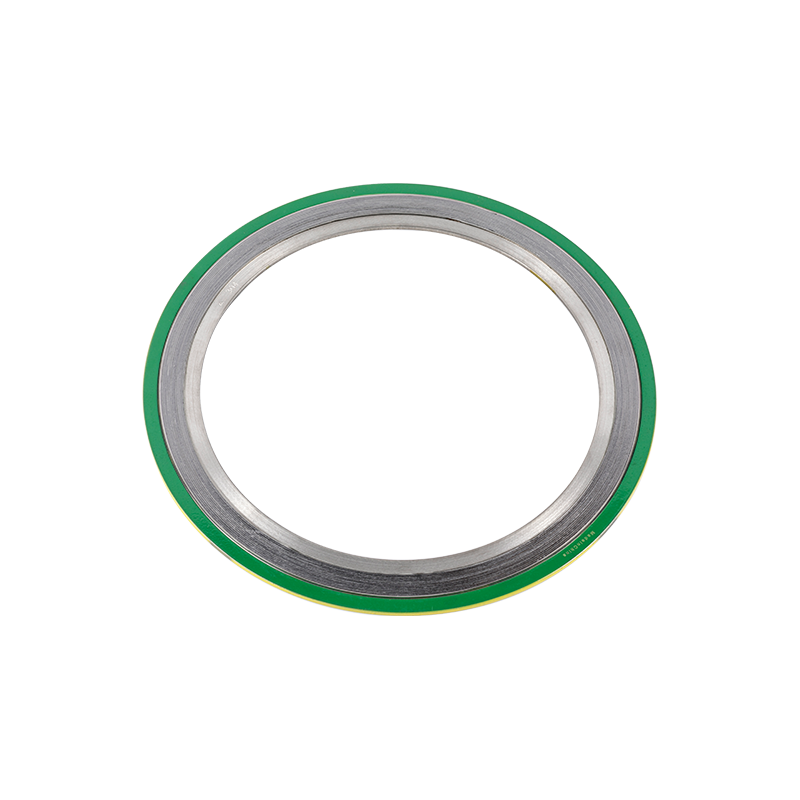

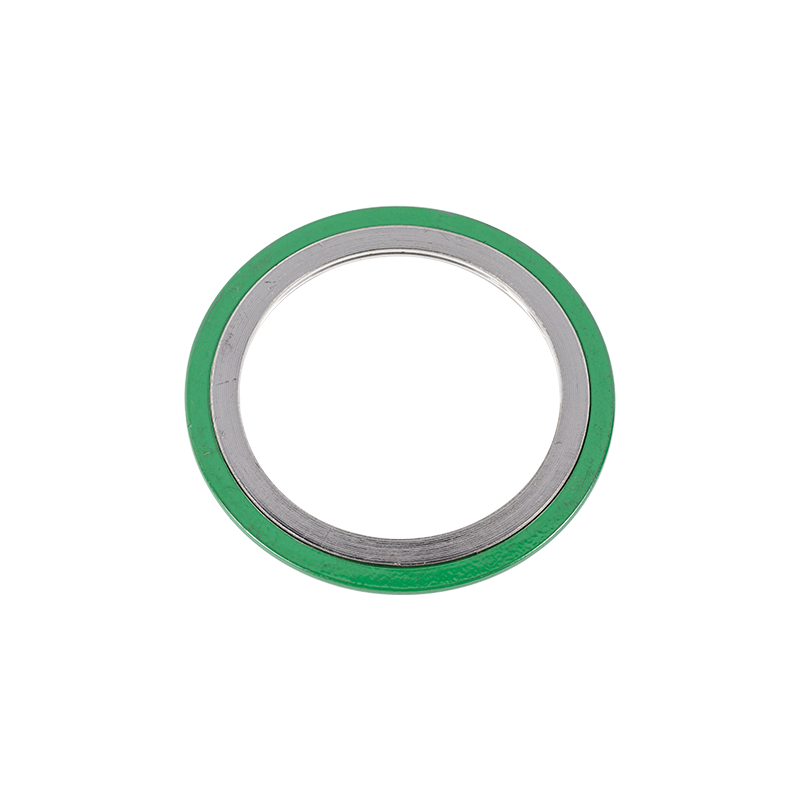

The functions of ring spiral wound gaskets include:

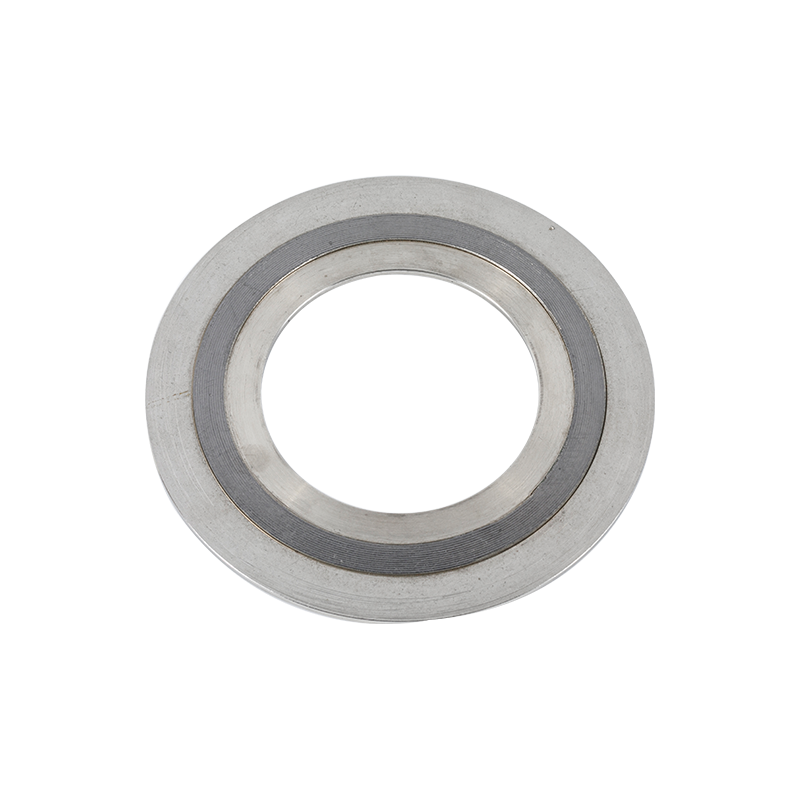

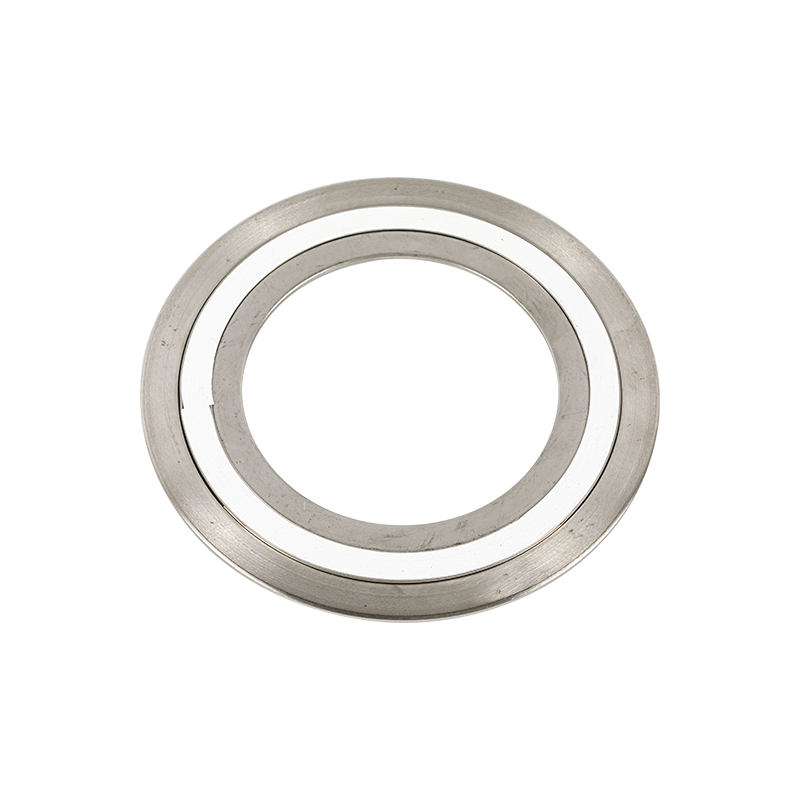

Sealing: Ring spiral wound gaskets are primarily used to provide a reliable seal between two mating surfaces, typically in high-pressure or high-temperature applications. The gasket's design, which includes alternating layers of metal and filler material wound in a spiral pattern, allows it to effectively seal against leakage of fluids or gases.

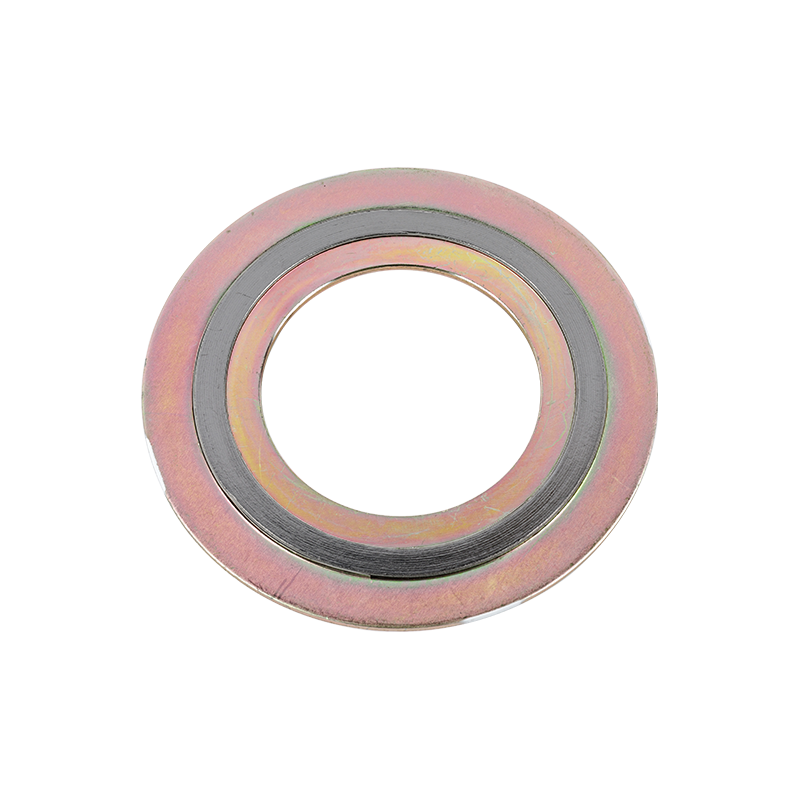

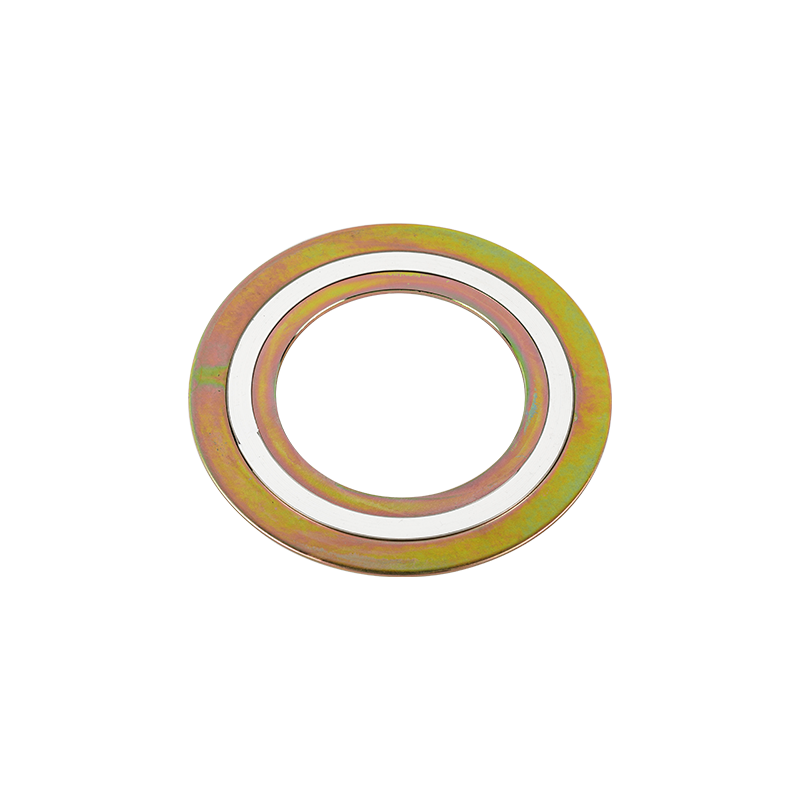

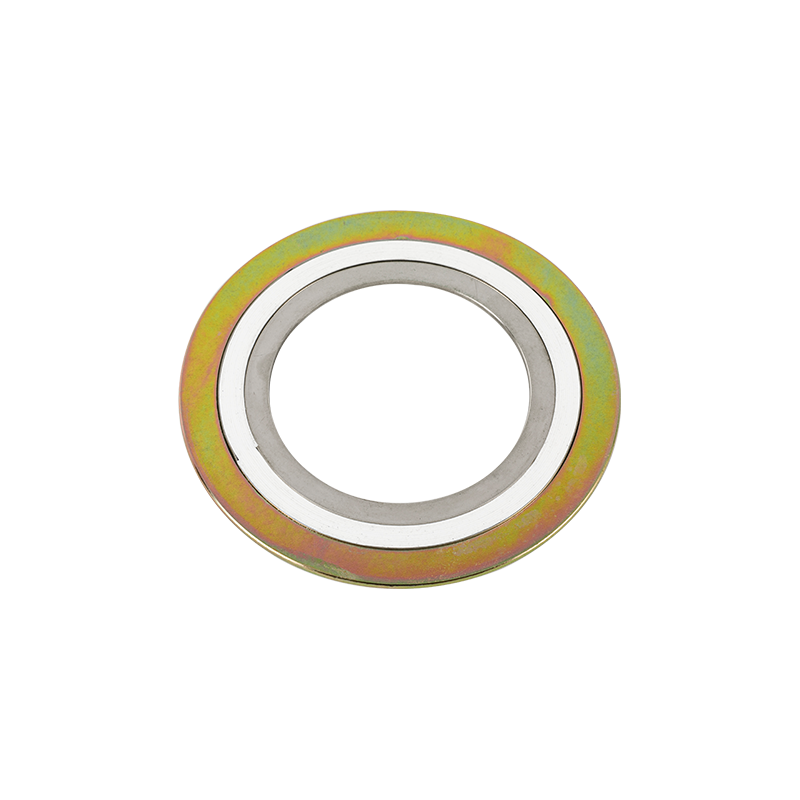

Pressure resistance: These gaskets are designed to withstand high-pressure environments. The combination of metal and filler material layers provides structural strength and resilience to maintain a tight seal even under significant pressure differentials.

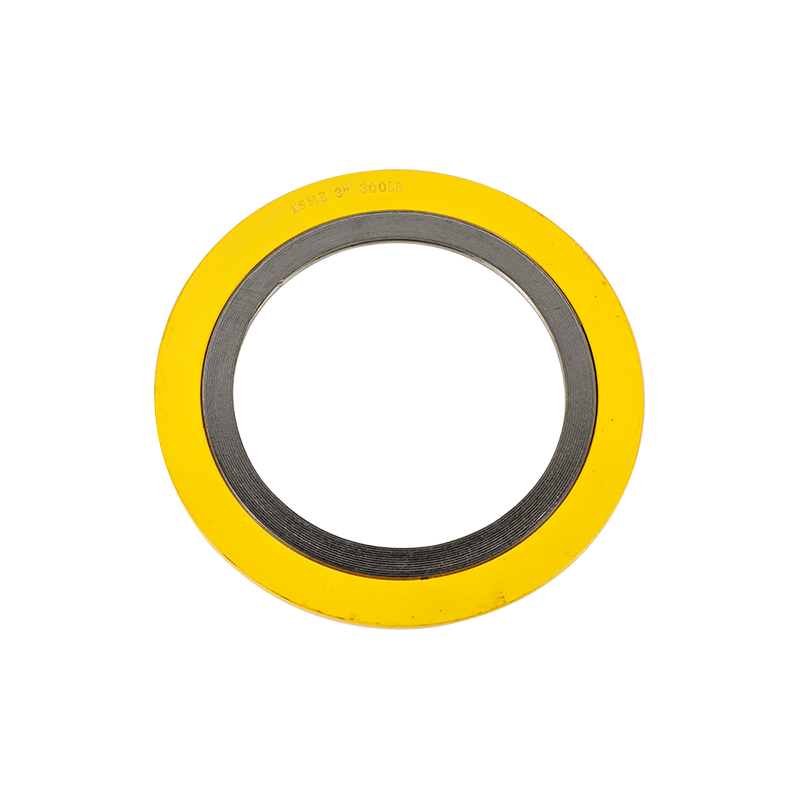

Temperature resistance: Ring spiral wound gaskets are capable of withstanding extreme temperatures. The choice of materials for the metal and filler layers can be tailored to specific temperature requirements, ensuring that the gasket remains effective and does not degrade or lose its sealing properties.

Chemical resistance: These gaskets are often used in applications where resistance to a wide range of chemicals is required. The selection of appropriate materials for the metal and filler layers ensures compatibility with various fluids or gases, providing resistance to corrosion and chemical attack.

Flexibility and adaptability: Ring spiral wound gaskets can conform to irregular or non-standard flange surfaces, allowing them to accommodate variations and imperfections in the mating surfaces. This flexibility helps ensure a tight and reliable seal even in challenging or non-standard flange configurations.

Longevity and reliability: When properly selected and installed, ring spiral wound gaskets can provide long-lasting and reliable sealing performance, minimizing the need for frequent maintenance or replacement.

English

English

中文简体

中文简体